What is material flow?

The material flow is the most important factor in a production company because products are created from materials. Only if the products are sold can the factory cover its costs. Therefore, it is imperative to move the material between the appropriate steps of the value chain directly and as quickly as possible.

When looking for a definition for material flow, you will come across different sources (VDI 2689, REFA …) though all essentially agree in their individual contexts:

The material flow is a sequence of processes ranging from the extraction of raw material via its processing, reprocessing and machining up to the finished product and delivery to the end consumer.

Basically, a distinction is made between in-house and external material flows which, in turn, has influence on the approach for material flow planning.

External material flow

Whereas the external material flow is usually performed by logistics service providers in conjunction with other customer orders, the in-house material flow usually falls into the company’s own responsibility.

In-house material flow

In most cases, the in-house material flow starts with the delivery of raw materials, parts or also subassemblies to the incoming goods warehouse and ends in the outgoing goods department with the delivery of finished or also semifinished products. Thus all transport processes between incoming and outgoing goods warehouses are part of the in-house material flow.

This can be realized by way of different transport means. On the one hand, there are personal transport means, such as forklifts, tugger trains or hand trucks, and on the other hand, there are non-personal transport means, such as roller conveyors, unmanned transport systems and racking storage and retrieval machines.

The objective is to minimize the workload associated with the material flow, as a result of which automatic transport systems are used to a growing extent.

Since there is normally no value creation in the product through the transport, despite all optimizations, the material flow should always be reduced to the transport processes that are absolutely necessary.

Material flow - waste or necessity?

The original theory of lean manufacturing by Taiichi Ohno differentiates seven types of waste. These types can be kept in mind very simply by way of the acronym TIMWOOD.

Two types of waste – transportation and motion – already depend to a large degree on the layout design; the type of waste ‘transportation’ refers directly to the material flow. Transports are definitely necessary because several processes in a factory are performed in different workplaces. Whether or not they are really necessary in their current scope depends on the design of the layout. Material flows often run back and forth through the production, and the parts travel countless kilometers from the beginning of processing to the finished product. Significant optimization would of the material flows can be achieved by redesigning the layout, and the transport efforts could be reduced by approx. 10 … 30%. In other words: Not ‘Waste or necessity’ is the question, but “How can I design the material flow to avoid waste?“

How is the material flow acquired?

Generally speaking, it should be quite easy to acquire the material flows, though this often turns out to be a major challenge in practice. Theoretically each company has already defined its processes by way of its ERP system and the corresponding work plans and knows which materials, parts and products are to be transported from where to where. The appropriate transport means and batch sizes are stored via appropriate logistics modules. When looking at the real transport processes, however, you will often see that the planned processes do not coincide with the real processes.

Of course, it is possible to reduce this difference somewhat a bit by increasing the use of forklift guidance systems and unmanned transport systems. But what about all the other processes that are often more event-driven?

Data acquisition procedure

… no problem – you should proceed step by step:

- Mapping of the processes planned in the ERP system or using the existing work plans is sufficient for an initial acquisition of the material flows.

- If any information is missing or values are not plausible, this can be made more precisely by manual recording or surveying of the employees.

- If you want to be absolutely precise, there are meanwhile also indoor tracking systems with the possibility of recording the routes of pallets or forklifts.

The first two steps are usually sufficient to plan the processes and layouts.

Important specifications for acquisition of the material flows are:

- Specification of source and sink for the material flow (turning -> milling)

- Specification of the number of transports per time (14,200 transports per year)

- Specification of the transport means (forklift)

- Number of transport aids per transport (one pallet per transport)

- Number of parts per transport aid (100 parts per pallet

If only information regarding the source and sink is available, it is ‘acquisition of the material flows in terms of quality’. If the remaining specifications are also acquired in analog form, the material flows can also be acquired in terms of quantity. In this context, the term ‘transport batches’ is used.

How do I represent the material flow?

There are different possibilities to represent material flows, depending on the task definition.

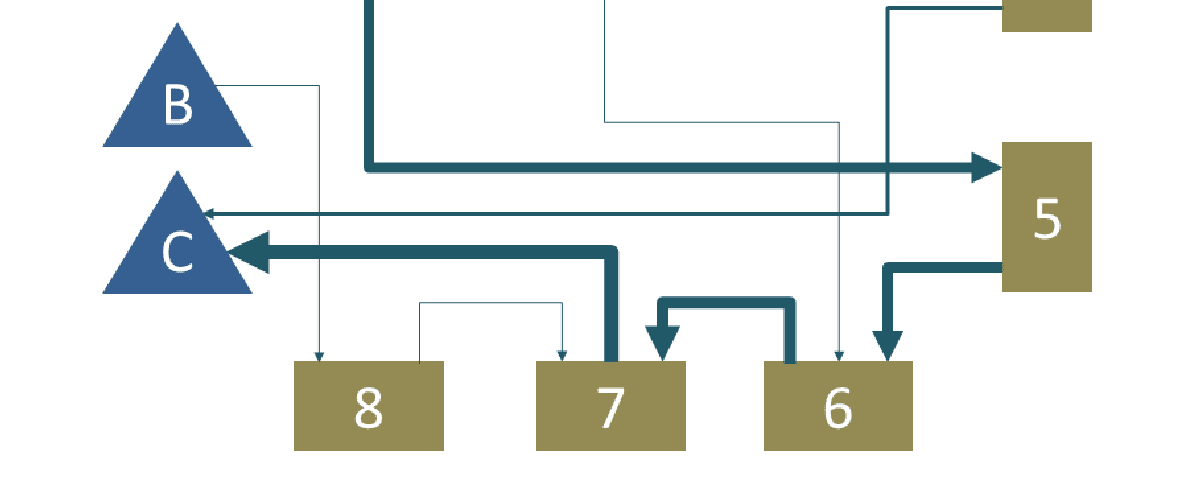

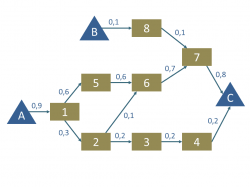

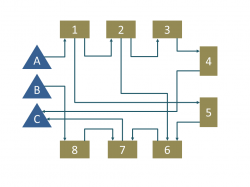

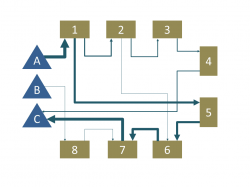

Process Graph

The simplest possibility is to map the material flow in a process graph. This is usually accomplished very quickly and easily, but can also become rather complex. It has found to be very advantageous to split the material flow by products or production departments. Since this type of representation is, however, a formal model, it is difficult to make reference to the real layout.

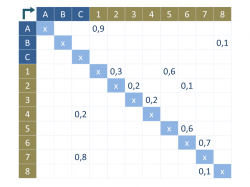

Transport matrix

Flow diagram

The representation of the material flows as a flow diagram is much more vivid, also with reference to the layout. The viewer can immediately identify the objects linked to material flows via the layout. This type of representation is often used in workshops where the layout is designed with paper and scissors and the material flows are mapped by way of drawn lines or needle and thread.

Sankey diagram

If, however, you wish to know where the main material flows are in the layout, i.e. where more or less material flows, there is no real alternative to using a Sankey diagram. In the Sankey diagram, the material flows are not represented as a simple link and thus as a mere extension of the flow diagram, but instead differentiated by using arrow widths proportional to the quantities.

The representation in the form of flow diagram, however, and similarly that of a Sankey diagram, can quickly come up against its limits if a large number of material flows is to be mapped. It can also be advisable to study the material flows in the different levels of hierarchy (workplace, department, building) of the factory.

Which influence has the material flow on the layout?

To be able to answer this question, you should consider that there are several factors influencing the layout. Especially in existing structures and buildings, the required and available space is often an essential criterion that has influence on the design of the layout. The available budget, of course, also plays an important role and is studied in the context between benefits and expenditure when the layout changes

But if all restrictions were to be removed, for example the shape and the size of the current premises or the form of the existing buildings, and you should effectively erect your factory on a greenfield site – which criteria would you then use to design your layout?

Exactly at this point the different flow systems of a factory come into play. Even if you are absolutely sure which products you wish to produce and which areas are required for the appropriate workplaces and warehouses, the question often arises as to how they are best arranged relative to each other. You will quickly find a solution by connecting the areas to be arranged by way of different flows. Since in addition to the material flow all further flows, such as the information flow, energy and media flows, but also the personnel flow often have lower priority with reference to the investment and operating costs, the material flow is often the flow system that determines the layout and thus has the most important influence on the design of the layout

Which effects has the material flow on my costs?

Direct effect on costs

The effects of the material flow on the costs can be significant. The parts often travel several kilometers in the factory before they can be shipped as products. To be able to cover all these distances, appropriate transport means are required, and their number is naturally reflected directly in the costs, both with reference to the investments and the operation.

Indirect effects on costs

What is, however, often disregarded are the resulting negative effects in the second instance. For example, longer transports result in increased passthrough times which are perceived negatively by the end consumer. Furthermore, the quality of the parts often suffers from longer transports as the parts are not transported finally packed. This also directly results in increased scrap of parts and rework.

To be able to nevertheless secure the material supply to the workplaces in case of long distances, it is needless to say that more buffer areas are to be provided, resulting in an increase in the inventory. This has direct influence on the occupancy costs and the fixed capital in material.

In view of all that, it should not be forgotten that the organizational expenditure also increases with the long distances and the increased number of transport means, areas and inventory items which is reflected in increased personnel costs.

One issue which increasingly comes to the fore is energy waste and the frequently associated environmental impact. In view of climate change, companies also bear the responsibility to reduce carbon emissions, and thus not only to consider their own costs, but rather to limit the costs for the world as a whole by helping to preserve our climate

In other words: It is always worth analyzing the material flows and performing material flow planning on this basis. Alone 10 … 20% of the production costs can be saved in the material flows by using various user experience.

Why is a material flow analysis so important?

To be able to optimize the material flow sustainably and efficiently, it is imperative to conduct a comprehensive material flow analysis. Such a material flow analysis covers all transport and warehousing processes to identify any deficits in the material flow and rectify them by way of appropriate measures with the objective to increase the efficiency.

Procedure material flow analysis

The approach for a material flow analysis is relatively simple and can be conducted in the following four steps:

- Specifying the objectives

- Specification of the objectives (e.g. reduction of the cycle times by 10%)

- Delimitation of the area under study (e.g. incoming goods department/dispatch)

- Recording the data

- Mapping of all transport processes in the area under study by way of value stream diagrams or a transport matrix – study of the material flows in terms of quality

- Acquisition of the material quantities to be transported (transport intensity) and the distances to be covered (transport routes) – study of the material flows in terms of quantity

- Assignment of the transport means and transport aids to the transport processes

- Acquisition of the transport batches (number of parts per transport)

- Acquisition of the fixed and variable transport costs

- Data analysis

- Calculation of the transport efforts as a product of the transport intensities and transport routes

- Calculation of the transport costs

- Representation of the material flows in the form of a Sankey diagram

- Display of material flows entailing high transport efforts in the form of a distance-route diagram

- Action potentials

- Deriving measures for structural modifications in the layout to be able to shorten the distances

- Deriving measures for an appropriate transport technology to reduce the number of transports or the transport costs

Result of the material flow analysis

The result of the material flow analysis are specific measures to realize the planned targets and to increase the efficiency of the production.

How do I design the material flow by way of material flow planning?

The reduced vertical ranges of manufacture, increased variety of variants, and increasing globalization make the material flows between and in the companies more and more complex. As a result, the material flows must permanently be adapted due to the continuous changes in accordance with the product life cycles that also become shorter and shorter. Against this background, sound material flow planning is imperative.

A planning basis can be created for the controlled material flows by mapping the in-house value-creation processes from procurement via production to dispatch. It is important to pursue an interdisciplinary and holistic approach since the different areas, processes and systems in a factory are to be considered as a unit.

Goal of material flow planning

The most important objective in material flow planning is to minimize the transport efforts.

The transport efforts consist of the quantity of material to be transported and the distance to be covered. The distance between the individual value-creation steps, in turn, decisively depends on the space required by the resources (areas/workplaces) and the required transport routes between them.

When mapping the value stream, the distance should tend towards zero wherever possible, i.e. direct transfer from workplace to workplace. In most cases, however, such a simple principle can only be realized in individual areas; the whole factory requires a holistic approach of optimization.

Such an approach can be realized by applying simple methods, such as the triangular method, and the experts from different departments (logistics planners, factory planners, planning engineers, production planners, building services planners, etc.) can realize a holistic material flow planning within the framework of common workshops.