Only CAD and pushing boxes were yesterday

The Institute for Integrated Production Hannover (IPH) advises customers in restructuring as well as in new factory planning and uses visTABLE®. We became aware of an interesting german podcast moderated by Jens Kruse with project engineer Andreas Nitsche on the topic of factory planning on Twitter.

In this, he reveals why factory planning is more than just a building drawing in CAD. He also explains what planning software needs to bring to the table and what a structured factory planning process looks like.

Here is a small excerpt from the interview (english translation):

Jens Kruse (moderator): “The layouts, that was what I mentioned earlier with the initial question. Is it still the case that you then really take a large paper plan or also digitally in some CAD software or similar or what methods do you use there now? If one says one would like to visualize that perhaps also for the customer or would like to go perhaps also times by the factory virtually, because I saw that also already times, that there is something like that. What do you use there, what do you employ?”

Andreas Nitsche (project engineer): “When I started here (at the IPH Hannover), there was the saying “pushing boxes was yesterday”. So in the past, it was really like that you cut out objects somehow. Whether it was just small boxes or shapes or even cardboard models of machines. And then, as you say, you pushed them back and forth on the drawing board, so to speak, to see if they would fit in at all? On this basis, of course, you could only qualitatively check how good or how bad it is.”

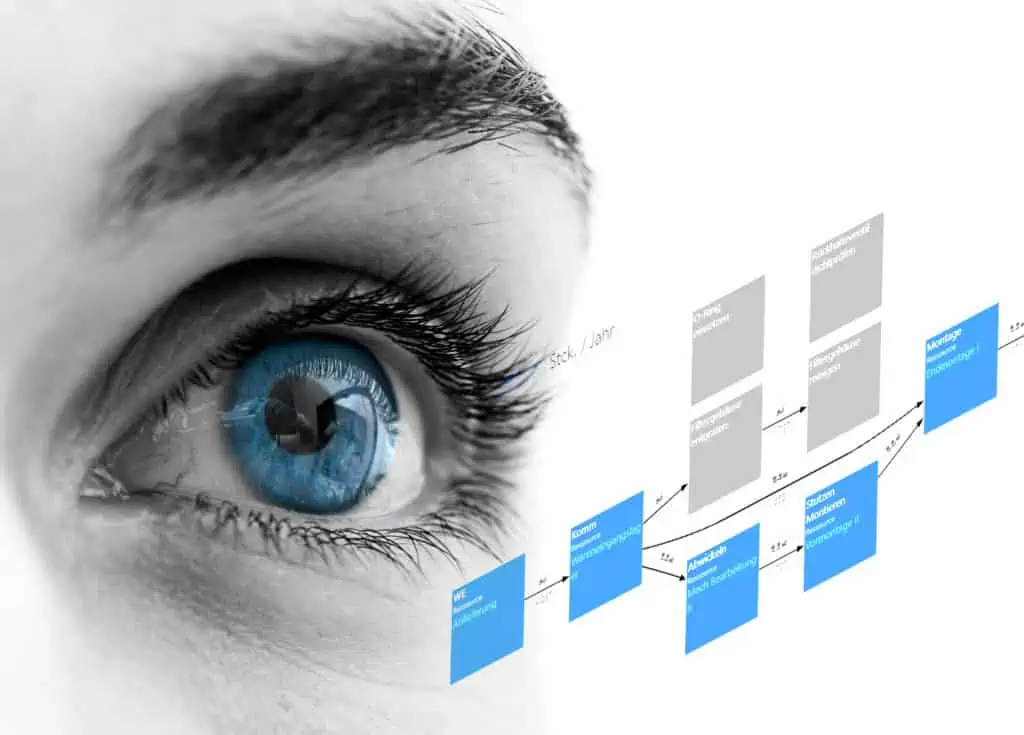

“Now, of course, we use software where we can map the layouts digitally, i.e. not direct CAD software, but in principle software that maps the layout itself and where you can map the material flows between the individual objects so that when you make a change in the layout, you can also directly evaluate the effect on the material flow, for example. And so you are much faster and more efficient in planning a layout.”

Background knowledge to the podcast

The physical flow of materials in a production facility has a significant impact on transport costs and transport time, read more here.

Closely related to the material flow are the terms value stream and the so-called line-back principle in planning.

If, in the case of “greenfield” planning, the building is accepted or completed before the area has been dimensioned, this can have serious consequences:

The aforementioned production planning and control is part of factory operations and works with daily updated data and is therefore very short-term. In comparison, factory design has a longer-term time horizon and is not up-to-date on a daily basis. You can find more about the distinction here

Virtual Reality (VR) can already be used very easily and cost-effectively in conjunction with visTABLE®. One possibility is the software IrisVR Prospect.

Convince yourself of the possibilities of the planning software visTABLE®touch.