Facing the new challenge with factory planning methods

The COVID-19 pandemic comes hard and unexpected for all enterprises, as it is hard for many of them to adapt their production. But such problems can be mastered with the methods of factory planning, also when looking into the future. After the crisis is before the crisis.

- COVID-19 comes especially hard for manufacturing enterprises.

- The fewest enterprises have a plan B. That’s why, it is as more as important to have it in crisis times.

- Methodical factory planning allows fast and flexible reactions.

The COVID-19 pandemic is a stress test – everyday and for each individual and especially for entire enterprises. They are faced with challenges that were previously hardly foreseeable. Complete branches of industry had to cease or convert their production during the lockdown in spring 2020. The mood is getting better again amongst the enterprises after this first lockdown, and many of them want to return to business. But is that the right decision in unsafe times? Is this approach also expedient in the future? Is this the right solution for the current and any further lockdowns? After all, no one knows how long the pandemic will accompany us and when the next crisis of this kind could strike.

An endurance test for manufacturing enterprises

The serious burden in spring can be seen on the COVID-19 topic pages of the Federal Bureau of Statistics (Destatis). The unemployment rate increased strongly with the beginning of the pandemic. At the same time, the production collapsed. How different German enterprises were hit by the pandemic can especially be seen at first glance when looking at the building trade. The pandemic was hardly felt there – in the manufacturing industry, however, strongly. Alone in April, the enterprises produced 25.3% less than in the same month of the last year. According to the Federal Bureau of Statistics, it has been the strongest decline since January 1991. In spring, many entrepreneurs were forced to introduce short-time work or to order their employees to work from home or even to lay them off. That was a severe endurance test from which the industry has not yet recovered even not in fall.

#Production in September 2020: +1.6% on the previous month. Production still 8% below pre-crisis level. https://t.co/WRw0GscPB6 pic.twitter.com/PndulTZtut

— Destatis news (@destatis_news) November 6, 2020

The expectations for the near future were also heavily dampened by the pandemic. In the lockdown month April, the Ifo index of production expectations was minus 51.0 points in April. Although it rose to -20.4 points in May again, this shows a clear relaxation, “But that only means that the nosedive is now becoming flatter,” says Klaus Wohlrabe, head of the Ifo surveys, regarding the significantly negative expectations in the industry.

Following the translation of a german tweet by ifo institute from June 8, 2020:

The German #industry expects a further decline in production in the next three months, albeit slower than before. The ifo index of #production expectations rose to -20.4 in May, up from -51.0 in April.

Furthermore, there is the uncertainty in short- and medium-term planning brought about by the current situation. The lockdown light in November visualizes everybody at the latest now that the COVID-19 pandemic is far from over. Nobody can say whether or not the anti-coronavirus measures will be extended or tightened. It is also not clear how many lockdowns have the enterprises still to face.

Thus, COVID-19 turns out to be the greatest challenge of our time for enterprises of the manufacturing industry. At the same time, however, there are also signs of hope and stories of success. Many enterprises used the crisis as a chance because the demand for protective equipment, disinfectants and medical devices increased rapidly. Production processes were converted virtually from one day to the next to be able to hold employees and further utilize the capacities of the factories to the full.

Why a sudden adaptation of the production is a problem for many enterprises

Conversion of the production sounds easily for persons not involved. In practice, however, there are many challenges to cope with. One of the greatest is: A plan B. Because an increase or reduction of the production by 30 to 50% in the shortest possible time is simply not planned by most enterprises. The pandemic shows that such a scenario is not a pure invention. And the current situation of a second lockdown clearly illustrates that a sudden adaptation of the production can be necessary at any time.

The solution to the problem is hence a blueprint of a conversion of the production or a possibility to respond comprehensively in the shortest possible time.

COVID-19 brings the flexibility of the production into the spotlight

The prerequisites for bringing flexibility in production into the spotlight are general conditions enabling enterprises to convert their production – completely or partially. In addition, it must be possible to increase or reduce capacities, and that as fast and flexible as possible.

Flexible production is not only the answer to a global situation of the crisis, but also to the future of the enterprises after the pandemic. It will reveal itself as one of the core elements characterizing the enterprises in the long run also after the COVID-19 era.

Therefore, it’s time to set the course for flexible production. We want to show you how factory planning methods will support you and your company in developing a plan B and to have it ready at all times.

With the methods of factory planning through the coronavirus crisis

If a new or adapted factory layout is required overnight, you must have a sophisticated methodology. At that point, digital factory planning comes to the fore. But this approach should not only be on the agenda in times of crisis.

Enterprises seeing factory planning as a continuous task can respond in everyday business in a fast and flexible manner and are not caught on the hop even by such challenges as a pandemic as this one. Methodical planning of machines, equipment and their arrangement within the entire production sequence results in adaptability and long-term cost benefits.

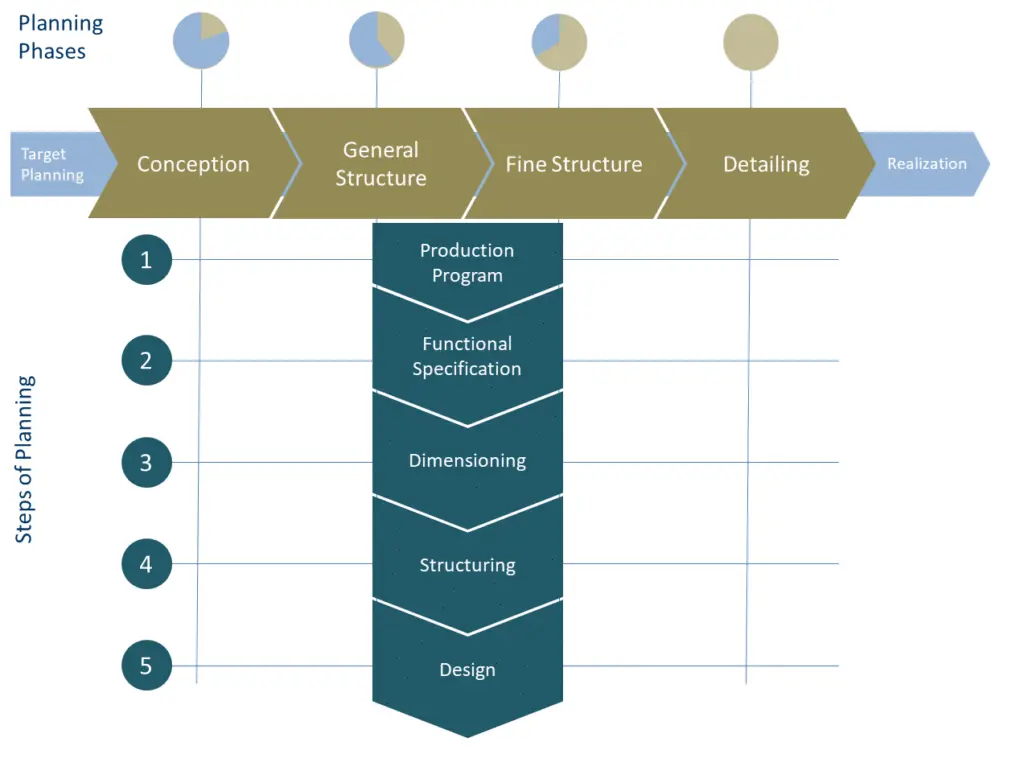

The factory planning process initially takes place from coarse to fine. It is a framework of factory or site development which helps here, with an enlarged level of detail in the sketches of the planning phases. How the relevant factory planning tools and methods are used is visualized by way of the planning steps below.

The basis of factory planning are the existing drawn or digital layouts from the site plan via the work structure to the production area up to the place of manufacture. A hierarchically structured factory model is a valuable basis for continuous optimizations and adaptations in crisis scenarios. Whenever it comes to restructuring of an existing factory layout, the work always starts from a detailed actual state, and the process of factory planning moves then from the fine to the coarse or bottom-up.

It is mostly not necessary to plan a factory completely new. It is rather that continuous site development and also quick adaptation to new challenges – either permanent or limited in time – are required. Thus, systematic, continuous factory planning provides the perfect framework to be able to manage crises also in the future.

Crisis-proof also in the future

The methods of factory planning cannot only be used to manage crises, but also in “quiet” phases of everyday business because big and small needs for change are waiting to be managed regularly. It can be decisive to have own know-how and state-of-the-art tools. Appropriate experts and resources are not only fully booked and consequently rare in crisis times. In addition, every external service provider must first understand and familiarize himself with your situation in order to be able to adapt your strategies.

Another aspect is the connectivity, i.e. whether or not and how the externally elaborated planning results can be used further in the future. Own model and databases meeting the requirements with reference to factory planning methodology seem to be expedient.

All this is reflected in the software solution used for factory planning. The systems of the service providers are typically highly specialized expert tools designed for use in complex planning projects. The operation and controllability of this scope of functions is reserved to users who do nothing else day after day. But most of the manufacturing companies simply do not possess the appropriate size to be able to utilize the planning capacities of such specialists and systems continuously. The aspect of straightforward operation is therefore essentially more important for most enterprises when selecting a software for their own factory planning than a wide scope of functions.

After the crisis is before the crisis – even if this may sound like a cliché in this context. It does not matter whether the next crisis will be a new lockdown or an increased demand for an own product which needs to be satisfied within a short time. Therefore, now is a good time to prepare.

Learn more: Factory planning – Important facts

No problem, simply subscribe to our Blog-News!