Simplifying your approach to digital factory.

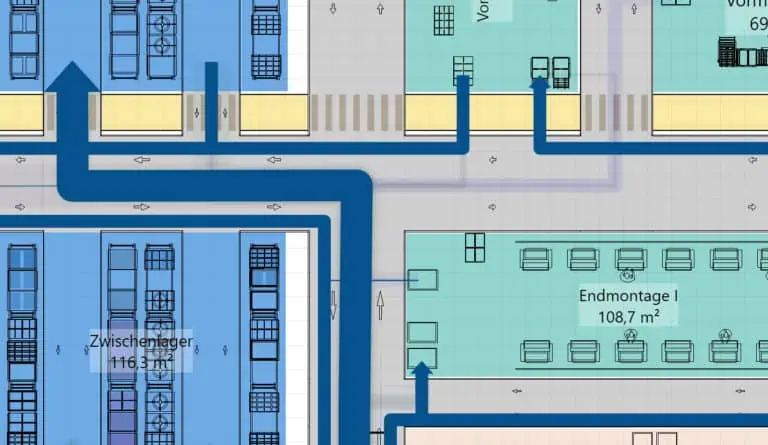

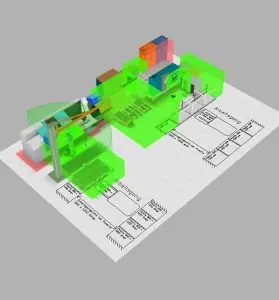

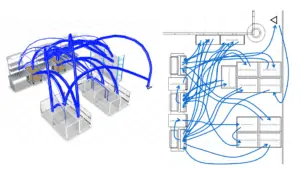

visTABLE® is the leading software helping manufacturing companies with the tasks of factory layout design and material flow analysis. Complex CAD tools and paper workshops are no longer required.

Unique 3D Library comprising 3000+ items

What our customers say

Expand your knowledge in visTABLE®-Blog

Why you should use visTABLE® software?

CAD drawings, Excel spreadsheets, inventory lists and floor plans are continually in need of troublesome manual updating, because no-one knows how and in which form the results of internal moves are best documented.

Your superiors or customers demand meaningful data as the basis for their decisions, for example floor space use and distribution, unused space, transport costs or conversion plans.

PowerPoint, Visio, Paint or SketchUp have already been used in the past, but all failed to deliver the required scope of answers to your fundamental questions. In some cases, the layouts are not to scale, and the material flows are drawn freehand – if at all. Your logistics specialists plan the supplying of containers or picking activities, but then document their implementation in the form of sketches or coarse drawings.

You are thus unable to enter modifications yourself. To keep drawings up to date, you must constantly seek out the corresponding experts in the company, and ideas can only be developed by way of extremely time-consuming trial and error. It seems to take forever before these ideas are implemented in the layout – however good they may be.

Your gut feeling tells you that there is always scope for improvement. As you lack suitable easy-to-use tools, however, you have always been forced to rely on this feeling. But you would much rather have sound and reliable data at your disposal, so that decisions can be made quickly and transparently for everyone concerned.

Thanks to the 3D library (3000 objects), it is amazingly easy to get started in 3D factory planning. A large part of the layout can already be created without costly and time-consuming data acquisition.