Many readers have perhaps already been in a similar situation: Conversion of the ERP system is still in progress. An important customer has just called with complaints about the recently completed order. And now it has been decided to switch to driverless transport because the visiting representative gave a very convincing presentation. How can your planning project succeed? Before you know it, the following image is conjured up in your mind’s eye:

You can’t see the forest for the trees, as the saying goes. But where should you start?

There is a tale of two woodcutters which could point you in the right direction. One of the two could never understand how his colleague managed to chop down more trees despite taking so many more breaks.

To cut a long story short, there is nothing to be gained from just working as fast as possible in your accustomed manner. The absolute first priority should instead be to ensure the prerequisites for efficient working.

Perhaps you are already beginning to realize that planners here and now are not really focused on improving their efficiency. That can at best be described as careless. Because at the end of the day, one thing is usually true: Many operational difficulties could have been alleviated with a more forward-looking approach. Or even avoided altogether.

Do you want to sharpen your own axe, i.e. the tools you use in your work? If so, the following six principles will almost certainly help you to achieve your goal.

Principle 1: Subject external consulting services to thorough scrutiny

Is planning for you a classic make-or-buy situation, which almost always ends in the commissioning of external consulting services?

Consultants will often bring extensive experience gained from projects with other clients, and your company could thus benefit from synergy effects. They are highly specialized and are not distracted by day-to-day business matters. There is no risk of blinkered tunnel vision. They may also be acquainted with relevant grant programs or have excellent connections to research institutes.

But one question which must be permitted is whether the consultant is truly interested in a sustainable solution. And what happens next, after the project is completed? If you have once made yourself dependent on external services, it is extremely likely that you will fall back on external support for the next project. What very probably falls by the wayside in this scenario is the opportunity to build up in-house planning expertise in the sense of potential for long-term cost savings and personnel development.

In the meantime, group planning processes implemented with in-house project teams (see also Principle 6) are seen as a serious alternative to external consulting. So making your planning project succeed also means relying on the experiential knowledge of your own staff.

Principle 2: If planning yourself, then plan digitally

Analog was yesterday; digital transformation is now omnipresent. Legacy tools such as magnet boards or brown paper may seem practical at first sight, but they are technologically outdated and also do nothing to impress observers.

These tools are furthermore a source of avoidable and unnecessary media disruption. Documentation of the different project states and planning variants, for example by way of photographs, is quickly revealed as a “time-waster”. This may also have a demotivating effect on the project participants. The same applies to obligatory redrawing or remodeling in the software to enable results to be utilized. In addition, information is often lost at the interfaces.

Another disadvantage is that the aforementioned analog vehicles leave no room for ad-hoc evaluations of variants, whether via performance indicators or dashboards. That is here in the nature of things and can easily become a management risk.

Principle 3: Use simple tools

If you intend to use a planning tool that integrates seamlessly into your current business processes, then you are looking for a turn-key solution. As simple as opening a door – insert a key, turn, done.

In practice, however, it is usually not quite that simple. Fortunately, there are a number of basic premises which can be applied: Proceed in small steps, but in return continuously. Constantly reflect on your expectations and reality. In short, there is no such thing as a 100% solution.

Specialist software such as that required for process simulations, furthermore, can only be mastered through regular use. If the last project is already some time ago, you will probably have trouble finding your way among the abundance of functions and menus – not to mention the need to work efficiently under deadline pressure. It will often also be very time-consuming to gather all the necessary data.

Consistent adherence to the KISS principle, on the other hand, can help you to reduce the complexity of the tasks ahead when assessing and selecting a digital tool. The following prerequisites should definitely be met:

- Concentration on the initially imperative functionality,

- Intuitive handling,

- Integrated and meaningful visualization of the results,

- Good, media-based documentation.

It can then be expected that the need for repeated familiarization will be minimized, and the planning results achieved can be communicated transparently. Planning projects succeed probably more often with user-friendly software.

Principle 4: Copy, paste & share

Why continually re-invent the wheel? Make immediate use of existing solutions whenever possible.

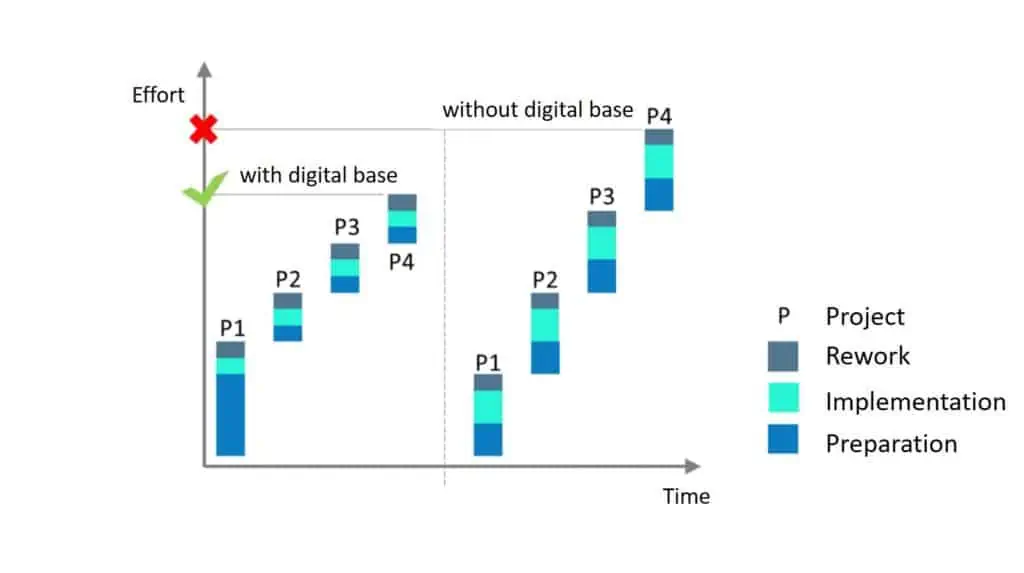

It is true that there is a certain initial outlay to establish a digital base. But over time, this will be compensated as the individual outlay for later projects is reduced (see diagram).

A practical example is the creation of company libraries to cover the standards which are used recurrently for production equipment. Further synergy effects can be achieved by sharing the arising best-practice solutions between business units.

Principle 5: Involve digital natives

Young career-starters obviously tend to possess little practical experience. That is only natural. But when it comes to the handling of information and communication technologies or social media, they are frequently one step ahead of the “old hands”.

They often enjoy simple access to digital tools and may already be fully conversant with relevant topics through previous internships, student project work, etc. In combination with experienced colleagues, they are able to form powerful teams. And a former newcomer could well evolve into a valuable member of staff in the future – the keyword here is staff loyalty.

Principle 6: Planning in a team as standard

Nowadays, teams are the clear preference over individuals. The lone wolf working from a private hideaway is a thing of the past.

Plan as a team and pool the opinions and expertise of all the key people. Preliminary decisions can then be reached more directly and many of the “extra laps” which often cost so much time can be eliminated.

Boost transparency by sharing your planning results across the company, for example by distributing viewer versions of your planning software. Many technical developments from the consumer field have since entered the B2B sector. They could help with practical implementation of the team principle. Current examples include flexible OLED displays and interactive, large-format whiteboards.

Conclusion

We believe that the six principles outlined here will help you to tune your planning processes to maximum efficiency and thus to ensure that your planning project succeeds also in the future. Or to come back to the tale mentioned at the beginning: With a sharpened axe, it will become all the easier to chop down your trees.

No problem, simply subscribe to our Blog-News!