Part 1: Significance of adaptability and the challenges involved

The adaptability of a factory is a potential key to success. Our aim here is thus to illuminate strategies, technologies and challenges associated with flexible and future-proof production environments. This blog series shows you how companies can secure competitive advantages through adaptability and flexible factory planning.

- Factories are subject to constant change due to internal and external factors

- Various strategies are available to company owners

- The PLUG+PRODUCE principle lends companies the necessary flexibility

Introduction

In the world of factory planning and factory operation, the ability to adapt to changing framework conditions is of decisive importance. After all, industrial production enterprises see themselves confronted with constant changes to the environment in which they operate. “Adaptability” is the keyword under which various scientific concepts offer answers to such change. Experts from both industry and science are agreed that fast reactions, flexibility, mobility and interconnectivity are the features which future-proof factory systems must offer.

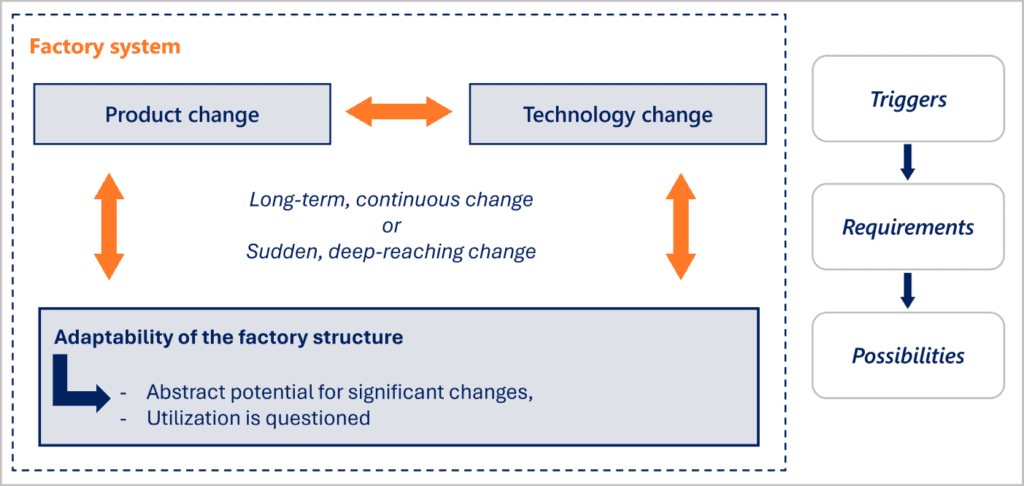

The changes faced by factories can have both internal and external causes. New products and technologies are primary triggers for adjustment processes in factories. Product and technology changes are often mutually dependent. External turbulences such as market changes may similarly give rise to significant need for adjustment. Adaptability is the solution.

But what exactly does adaptability mean in this context? What are the characteristic features and concepts? Which challenges arise for engineers and company owners? And how can we best tackle the continuous changes in factory practice?

These are the questions we want to explore in our three-part blog series. We will take a closer look at the essential aspects of adaptable factory structures, as well as the triggers and causes of change in factories. Furthermore, we will introduce you to a concept that places a focus on variability in factory planning.

The discussion draws upon the following literature: Torsten Hildebrand, Katja Mäding and Uwe Günther; PLUG+PRODUCE Gestaltungsstrategien für die wandlungsfähige Fabrik (PLUG+PRODUCE planning strategies for an adaptable factory); ISBN 3-00-016076-0.

Adaptability and its triggers

Adaptability defines the ability of a system to respond actively to changes in its environment and to adapt accordingly. In the context of factory planning, adaptability refers to how a factory structure is able to react flexibly and effectively to changed demands. An adaptable factory structure enables the elements of a factory system to be arranged and interconnected in a manner that permits significant later modification.

Various factors can trigger changes in factories, for example new products, technologies, market conditions and internal processes. Product innovations and technological advances are the two main drivers for change in a factory environment and are often mutually dependent. External and internal turbulences may similarly lead to change by increasing the requirement for adaptation and flexibility.

Strategies for reaction to change

Factories adopt various strategies to enable them to react to such changes. A stability-based strategy aims to preserve the existing factory structure and minimize adaptation. The general assumption is that little or no change is to be expected.

The opposite case is an adaptation-based strategy that provides for active modification of the factory structure in order to adapt to new requirements. The central idea here is that changes to products and technologies necessitate significant structural adaptation.

The planning of adaptable factories brings both challenges and opportunities. On the one hand, the factories must be able to adapt quickly and efficiently to changing requirements. At the same time, adaptable factories are able to react with greater flexibility and agility to market changes and can thus gain a competitive advantage. An adaptable factory structure also accommodates significant later modification. Paying due attention to adaptability can thus establish a performance reserve that can be utilized as and when need arises.

The choice of a particular strategy depends on various factors, including the type and intensity of changes and the long-term objectives of the company.

PLUG+PRODUCE: A variable concept for factory planning

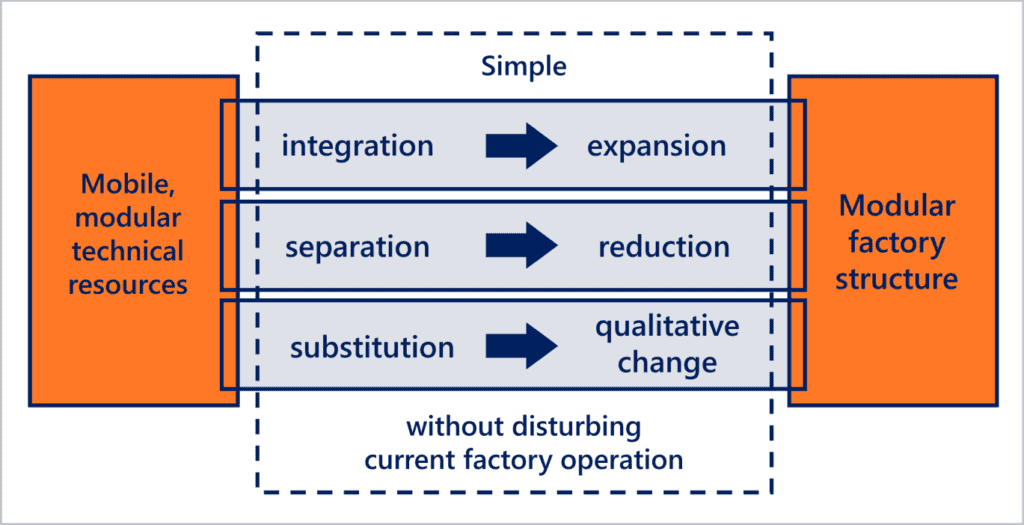

The PLUG+PRODUCE principle is based on the philosophy of plug-and-play and permits efficient factory expansion and adaptation. Modular structures allow resources to be integrated, separated or replaced without interrupting operation. This provides for fast reactions to change and efficient adaptation to new requirements.

The vision of a factory as a modular system is one step towards the objective of standardized factory structures that can be adapted quickly and with minimum expense to different locations and requirements. Standardization and modularity promise fast realization and possibilities for step-by-step expansion without disturbing current operation. The planning of such factories takes into account the needs of the market and the capabilities of the applied technology to guarantee efficient and flexible production.

Importance of adaptability in factory planning

To summarize, adaptable factories are characterized by their ability to adapt continuously to changing market conditions, technological developments and customer demands. A combination of organizational, technological and cultural measures enables factories to become more agile, more efficient and more innovative, and thus to remain successful on the market in the long term.

The importance of adaptability in factory planning thus cannot be overemphasized. Flexibility and adaptability are decisive factors for the long-term success of a factory. Through the targeted planning of adaptable factory structures, alongside the definition of suitable reaction strategies, factories can bolster their competitiveness and gear up for future challenges. Adaptability, after all, is not just a one-off measure, but rather a process of continuous adaptation to a changing environment.

Looking ahead to Part 2

After this introduction to the subject, the second article in our series looks at the principle of a standardized modular factory (SMA) in more detail. What does the planning concept look like, and how can production capacities be expanded step by step? Our next article will point you to the answers! Simply subscribe to our blog and you will be notified as soon as Parts 2 and 3 of our series “Adaptability in factory planning” are online.

No problem, simply subscribe to our Blog-News!