Part 2: The standardized modular factory: An innovative concept for modern factory planning

In the first part of our article series, we discussed the importance of adaptability and its requirements for factory planning. The second part of our blog series will illuminate the concept of standardized modular factory. What does it look like in theory and which are the advantages? Our article will point you to the answers!

- Comprehensive process of standardization with the aim of optimization of the manufacturing and logistics costs

- The concept provides for standardization and, in addition, promises risk reduction on changing markets

- Standardized modular factory as a future model illustrating the continuous adaptation of the production capacities

Introduction

The requirements of globalization and breaking into new markets demand new, flexible strategies from the companies. Traditional approaches, such as the installation of branch offices, or mergers entailing great financial risks and extensive planning times are often not efficient enough. This is the point where the concept of standardized modular factory comes into play which forms the basis for the PLUG+PRODUCE philosophy. This strategy aims to fast expansion through standardized, modular factory systems with minimum risk. The vision is to standardize factories in such a manner that they can be replicated as a fast-food restaurant and adapted to the specific conditions of the appropriate location. This promises a solution ensuring high scalability and adaptability, which is advantageous in particular, in global, dynamic markets.

Holistic process efficiency and expansion step by step

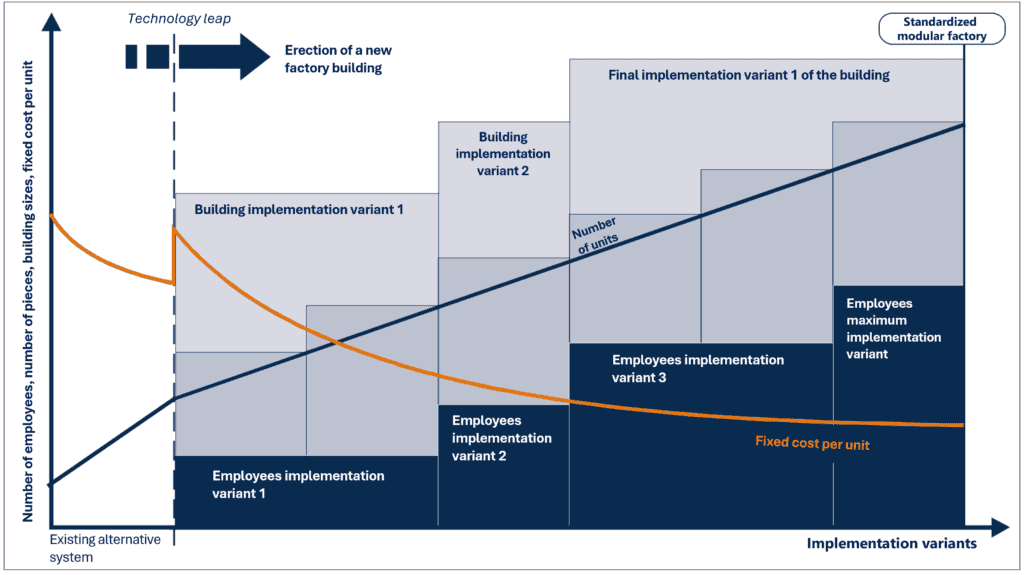

The standardized modular factory pursues a holistic approach for process efficiency. Standardized production systems and modular design enable factories to be expanded step by step and in accordance with the actual needs and requirements. This permits flexible adaptation to different market requirements and minimizes disturbances in day-to-day operation. Fast realization and the possibility of developing international markets in an efficient manner are to be regarded as the essential advantages of this approach.

A standardized modular factory can start initially with a minimum configuration to save costs and minimize risks. This configuration can then be expanded step by step in accordance with the demand on the market and various other economic factors. Each expansion stage is designed in such a manner that it can be implemented without interrupting the day-to-day operations.

What is a standardized modular factory?

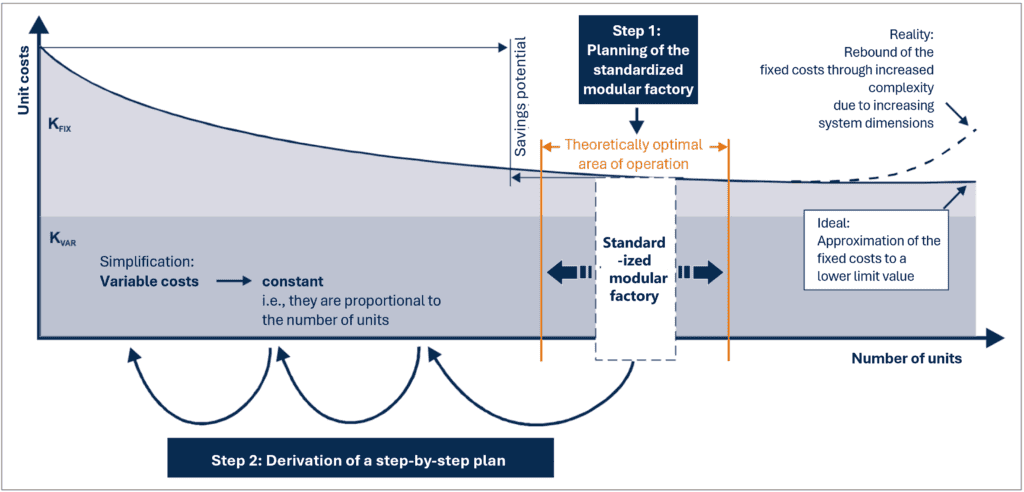

The standardized modular factory is the result of a comprehensive process of standardization. The objective is to achieve an optimum of the manufacturing and logistics costs which is applicable for different operating states and periods. The maximum capacity represents the optimum of the total costs whereas other operating states constitute expensive and less perfect intermediate solutions (“suboptima”). If the market demand is greater than the capacity, the factory is duplicated and not expanded instead. This promises an efficient utilization of the resources and quick adaptation to market changes.

A characteristic feature of the standardized modular factory is its ability of fast duplication. If the market demand exceeds the capacity of a standardized modular factory, not the existing factory is expanded, but a new, identical factory is erected instead. This eliminates both the complexity and the costs incurring in conjunction with an expansion and ensures that the new factory can be started up quickly.

The planning concept of the standardized modular factory

The concept of holistic process efficiency is oriented towards utilization-focused harmonization of the resource usage. This includes dimensioning of the production equipment, allocation of the human resources and buildings with optimization of the total costs. The planning is performed independently of the current entrepreneurial restrictions and aimed at achieving minimum unit costs. A life cycle cost study helps minimize the total costs in the long term and maximize the efficiency.

A decisive component of this approach is the holistic discussion of the factory across all phases of its life cycle. In other words: All aspects of the factory – from planning via construction to maintenance and putting out of operation – are to be taken into account. This promises more precise forecasting and improved cost optimization.

Advantages of the standardized modular factory

The standardized modular factory is characterized by the following advantages:

- Fast realization: The modular design permits fast commissioning. It is especially important for a market that changes fast, with the time playing an important part.

- Flexibility and scalability: Capacities can be expanded step by step, permitting companies to adapt their production in accordance with the demand step by step, without producing unnecessary costs for overcapacities.

- Cost reduction: Costs can be reduced by using standardized processes and reusing documents and experience. This pertains both to the planning costs and to the operating costs.

- Risk minimization: Investments can be controlled and distributed more effectively, resulting in reduction of the financial risk, primarily in insecure markets.

Standardization and the standardized modular factory: No contradiction

Whereas standardization in production and processes has already been established, the standardization of complete factories is still new. This is the point where the standardized modular factory comes into play, offering an efficient solution through modularity and standardization. First approaches can already be noticed in the industry. A standardized factory, after all, can be marketed as a product and promises fast and cost-efficient expansion.

An essential aspect of the standardized modular is its ability to be installed at different locations, with a minimum of adaptations. This involves that the basic structures and processes are standardized, reducing the time required for the appropriate planning and licensing procedures considerably. The advantages of standardization include not only reduced planning and operating costs, but also improved quality assurance and faster launch to market.

The step-by-step plan for capacity expansion

The step-by-step plan enables targeted expansion of the production capacities with minimum risk. Starting with a minimal configuration, the factory is expanded step by step to meet the market requirements. The individual steps of the plan are designed in such a manner that the production capacities are expanded optimally and the fix costs per product are reduced to a minimum. This method does not only promise economic advantages, but also reduces the investment risk.

This step-by-step expansion enables companies to control and adapt their investments in accordance with the actual market development. In other words: Companies need not invest into a large plant or system before the appropriate needs actually exist, but can increase their capacities step by step in accordance with the demand. This reduces the risk and the financial load and provides for more effective control of the production costs.

The standardized modular factory as a model for the future

The standardized modular factory provides an innovative solution for the challenges of modern factory planning. Thanks to standardization, modularity and step-by-step expansion, it enables companies to respond efficiently and flexibly to market changes. The initial investment into planning and conception is compensated by far-reaching gains in efficiency and reduced risks. Enterprises relying on standardized modular factories are prepared better to make their way in a dynamic global world.

The implementation of the standardized modular factory concept requires comprehensive planning and exact analyses of the market requirements and production capacities. Companies must be ready to invest into new technologies and processes and to foster a culture of continuous improvement and innovation. With the right strategy and implementation, the standardized modular factory possesses the potential to increase the efficiency and flexibility of the production significantly and to give the companies a decisive advantage in competition.

Looking ahead to Part 3 of our article series about PLUG+PRODUCE

After taking a closer look at the principle of the standardized modular factory in conjunction with the answer to the question how production capacities can be expanded step by step, we would like to go into practice in the last part of our article. Where and how is the concept realized? Read Part 3 of our blog series to find the answers! Subscribe to our blog now, and you will be the first to be able to read the ending of our blog series “Adaptability in factory planning” online.

No problem, simply subscribe to our Blog-News!