The process of layout planning often produces several variants. This is mainly due to the fact that several, sometimes opposite target criteria must be taken into account. Another aggravating fact is that the decision-makers assume different perspectives when evaluating the layout variants which, in turn, aggravate an objective evaluation. This is often the beginning of lengthy discussions and many meetings for both the creator of the variants and the decision-makers. This can be bypassed by way of a cost-utility analysis that helps very quickly to find the objectively best solution. To this end, merely five steps are required.

Five steps to find the best layout variant with utility analysis:

- Definition of the evaluation criteria (targets)

- Weighting of the evaluation criteria

- Determination of the costs (efforts)

- Calculation of the utility values

- Selection of the objectively best solution

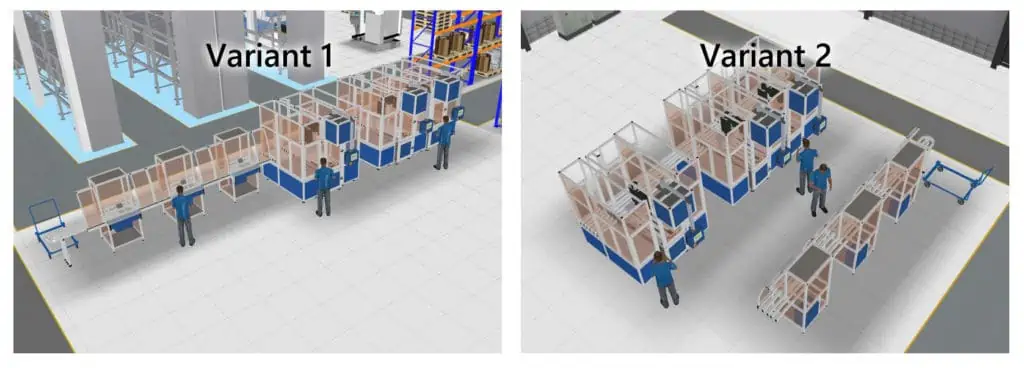

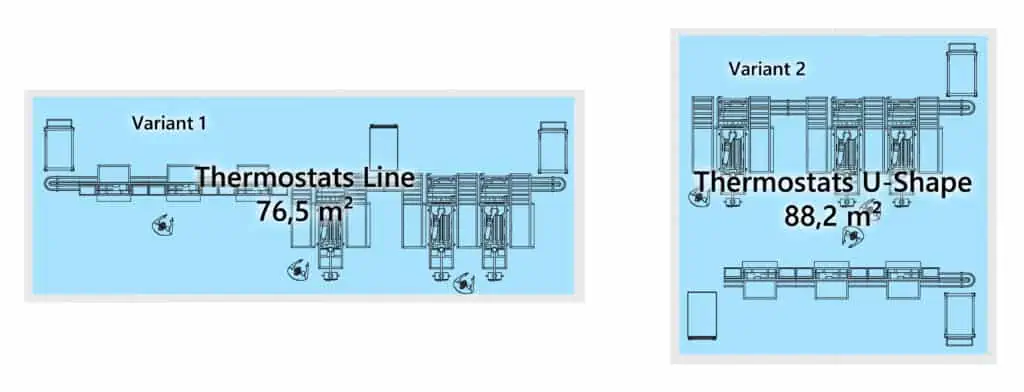

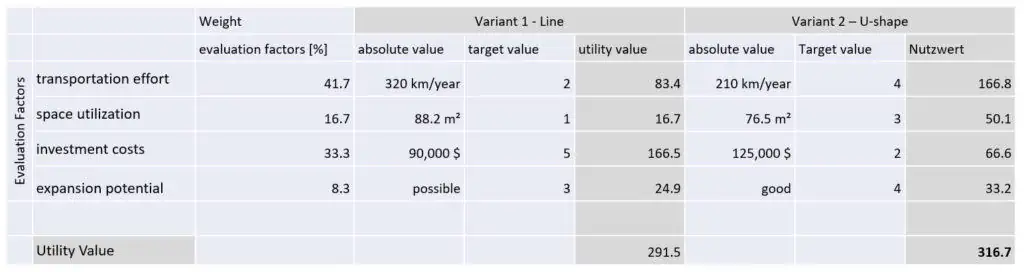

Let’s take a simple example to explain the principle of cost-utility analysis. The example deals with the decision as to whether installing a production line for thermostats as a line or U-shaped.

Step 1: Definition of the evaluation criteria (targets) for the utility analysis

The following points should be considered when defining the evaluation criteria:

- The evaluation criteria must be independent of each other.

- Only the most important evaluation criteria (max. seven) are to be considered.

- Layout variants identified as show-stoppers must be excluded immediately.

Since the decisions often involve costs, effort, and floor spaces, transportation and floor space use are the most frequently applied evaluation criteria for evaluating layout variants. In particular, transportation as one of the seven classical types of waste plays an important role. Further evaluation criteria could be e.g. investment costs, expansion capabilities, compartmentalization or restructuring efforts. Our little example refers to the following four evaluation criteria:

- Efforts in transportation

- Floor space use

- Investment costs

- Expansion potential

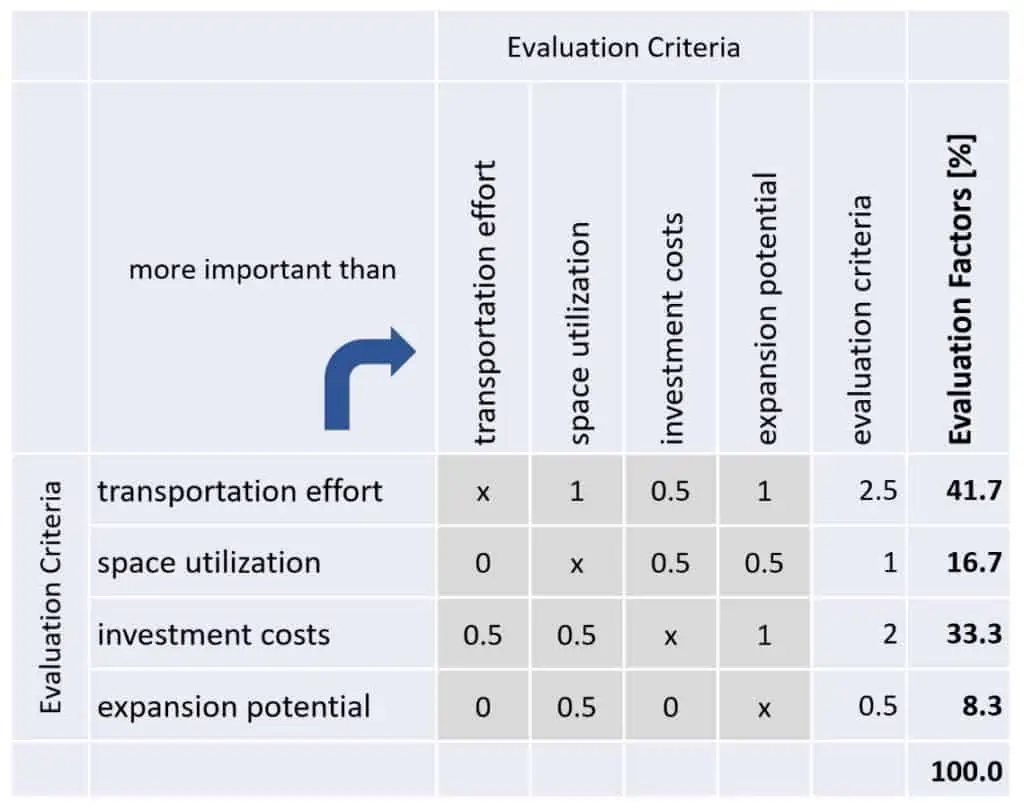

Step 2: Weighting of the evaluation criteria

Since it often happens that several persons with different imaginations are involved in deciding the layout variant, but finding the right decision is sometimes also difficult for yourself, the evaluation criteria should be weighted neutrally. The ideal method is the paired (or pairwise) comparison. A matrix is created, comparing all evaluation criteria against each other in terms of their relative importance. Important criteria receive the value 1, less important criteria the value 0, and criteria with the same importance the value 0.5.

This weighting can be conducted jointly in team, but in order to avoid long discussions already at this point, everybody should conduct this weighting himself and use the arithmetic mean of the evaluation factors as the basis.

The evaluation criteria ranking results from the sum of the evaluation points specified in each line of the matrix. The most important evaluation criterion in our case is transport effort.

Step 3: Determination of the costs (efforts) for the utility analysis

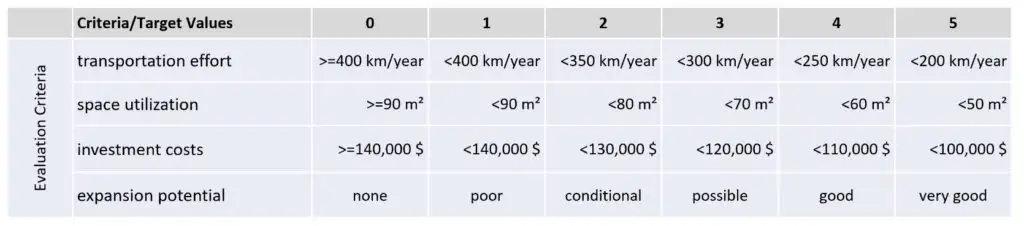

The costs or efforts for each layout variant are determined in the third step. The easiest way is to have concrete numerical values for transport effort or investment costs, for example. When using concrete numerical values, the term ‘cardinal evaluation’ is used. It becomes more difficult to apply evaluation criteria from which you can only say whether it is better or worse. This is called ordinal evaluation.

For better understanding and traceability, it is recommended to describe the evaluation criteria verbally and specify the underlying effort. The description for our little example looks as follows.

Transport effort:

The transport effort is the total of all efforts required to transport the products, subassemblies or components from one workplace to the next workplace or area. Transport effort is always the product of the number of transports and the appropriate distance in meters or rather kilometers. A cardinal evaluation is performed.

Floor space use:

The objective of floor space use analyses is to study how much space in m² is required for the layout variant concerned. A cardinal evaluation is performed.

Investment costs:

Investment costs include all costs in EURO which are required for installation and commissioning of the layout variant concerned. A cardinal evaluation is performed.

Expansion potential:

The term ‘expansion potential’ refers to the possibility of expanding the capacity of the production line by additional modules in the case of additional process steps. Due to the existing hall layout, a quadratic form can be realized easier than a rectangular shape. You could naturally also use the side ratio as the basis for cardinal evaluation, but ordinal evaluation was selected here since the detailed form of the production line can be compared with the restrictions of the site of installation in question.

The evaluation criteria with assignment to the corresponding target values are shown in the overview below. Scaling between 0 and 0.5 is very expedient; otherwise, there is the problem of differentiating the layout variants, in particular in ordinal evaluation.

When assigning the value ranges, it is recommended to map the range of values for the different layout variants. To be able to obtain an objective evaluation especially in the area of layout planning and in the case of possible changes in existing structures, variants should always correspond to the ideal layout that should be free of restrictions if possible. Thus you will get not only a comparing evaluation taking into account the existing restrictions, but also an idea of potential savings.

Step 4: Calculation of the utility values

The fourth step after the preparatory first steps is now just only to collect the utility values of the individual layout variants and multiply them with the weighting factors of the evaluation criteria.

Step 5: Selection of the objectively best solution

The layout variant with the highest utility value is objectively the best variant. However, this need not necessarily mean that this variant will also be realized. It is more expedient to objectively sort the different layout variants and, may be, further subvariants result from them, which will then be realized with consent of all persons involved. The cost-utility analysis definitely helps to design a structured and constructive decision-making channel, thus saving work, nerves and time.

To not miss this and other articles in the future, just subscribe to our blog

No problem, simply subscribe to our Blog-News!