The material flow matrix (also: transport, flow, or intensity matrix) is one of the best known and not least simple formal models for the representation of logistical processes in manufacturing companies. The following is recorded in it:

- Sources and sinks for material flow: In logistics, this refers to the locations (resources) from which material is transported away (sources) and/or which are supplied with material (sinks). Sources and sinks can be found in the form of warehouses, machines or workplaces. These must be positioned in a factory layout. That is why they are called “arrangement objects” in layout planning. Together they form one or more flow systems. Most arrangement objects are both, source and sink. The others are considered as boundary elements of the flow system (e.g. goods receipt and goods issue of a factory).

- Transport intensity: This parameter describes how often transports take place from a source to a sink in a unit of time. This is supposed to represent the logistics effort. In fact, however, it only captures one dimension of the transport effort. The second dimension is the distance between source and sink. This is not considered in the material flow matrix.

What is the meaning of transport intensity?

Read more here:

Material flow analyses in two dimensiones

The structure of the material flow matrix

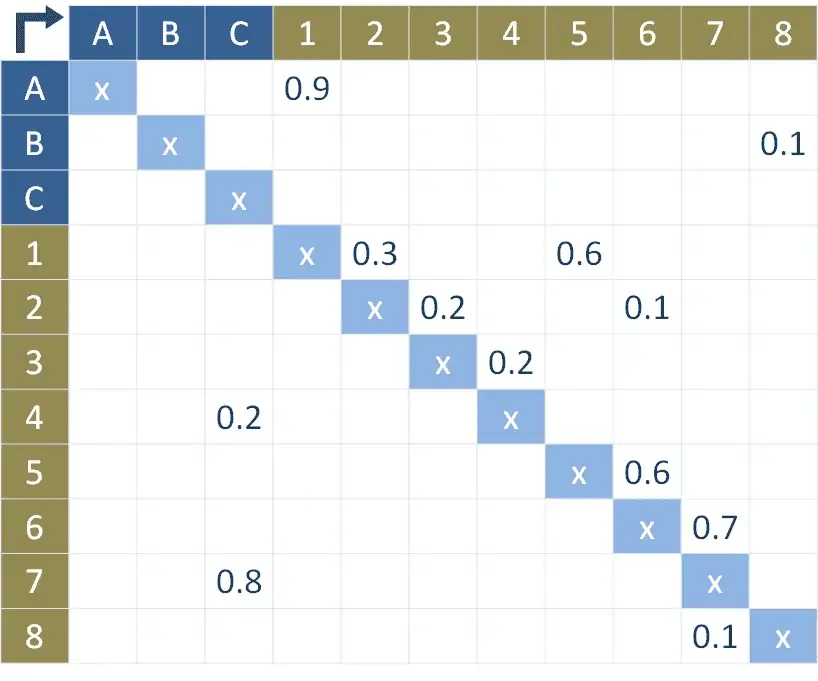

The material flow matrix is a tabular material flow scheme. All arrangement objects involved in the material flow are to be entered in the respective first column and row of the table. The first table field (top left) remains empty. For better orientation, the reading direction from source to sink can be marked in it. The matrix diagonal starting from the first field is blocked. The transport intensities are entered in the remaining fields.

Usually, the first column is used for the sources, the first row for the sinks. In the example shown here, the transport from object A to object 1 is entered in its intensity of 0.9 above the diagonal at the intersection of the matrix axes of A and 1. If there were counter transport from 1 to A, it would be entered below the diagonal. Thus the direction of the material flow is recognizable.

Use of the material flow matrix for planning

Algorithms can detect from the matrix structure whether the resulting flow systems are linear or networked. This is decisive for the strategy according to which the objects must be arranged in relation to each other in the production layout.

For the arrangement optimization of networked flow systems, for example, the direction of the material transportation is subordinate. For this purpose, upper and lower triangular matrices are added. The matrix fields then contain the intensity of the entire flow relationship, instead of the intensity of the directed transport.

For linear flow systems, on the other hand, the direction in the material flow is decisive for the optimal arrangement of the resources involved in the flow. For many manufacturing companies, designing linear structures for the entire supply chain is even considered an essential goal for simplifying the processes in logistics.

Therefore, the creation of a material flow matrix is particularly important for the analysis of the current state. The number of transports is used as a measure of intensity. These are counted between defined areas with source or sink functions and recorded in the material flow diagram. Tracking systems that offer a material flow matrix directly as an output format for Excel can help here. With some know-how, this simple form of mapping material flows can also be derived from an ERP system. So specialized consultants for factory planning often develop an initial quantitative basis for layout planning.

Advantages and disadvantages

A major advantage of this material flow representation is its simple form. This makes it easy to create and easy to process with software. Furthermore, it is the basis of heuristics for planning factory structures, e.g. for the modified triangle method according to Schmigalla.

A disadvantage is the high degree of abstraction. For example, flowcharts such as the Sankey diagram are much more clear and contain the same information about the material flow. However, this is of secondary importance today. Flowcharts have largely lost their practical significance for illustrating processes in logistics in favor of graphical software systems. Such software can display the material flow in terms of factory layout and allows targeted analyses for material flow planning. The material flow matrix is therefore very popular today in the planning of material flow and logistics, especially as an exchange format at Excel interfaces.

Related topics:

- What You should definitely know about material flow

- Material flow analysis in two dimensions

- How factory layouts depend on the value stream?

No problem, simply subscribe to our Blog-News!