Floor markings – can there possibly be anyone who has not encountered them at some time? They are to be found everywhere in our daily lives. Especially in these times of pandemic, floor markings await us in practically every supermarket and public building. They are intended to help us observe the recommended social distancing, and in this way protect our health and safety.

In the workplace, too, markings play an important role, but they are nevertheless often forgotten or treated with disregard during workplace planning and subsequent implementation.

Why go to the trouble?

If we look at the annual statistics on industrial accidents, there is clearly room for improvement. Worldwide, approx. 300 million people suffer accidents at work each year. And every day, approx. 6,000 of them die as a result of an industrial accident.

Tripping and falls while walking are among the most frequent workplace accidents recorded. Another common cause is a lack of awareness or underestimation of risks in the work environment of a company.

Such lack of awareness and underestimation of the potential risks are for me the principal reason why the subject tends to be neglected during the planning and later realization of industrial workplaces. No one trips and injures themselves when viewing a printed layout or CAD model. We are only awakened to the hazards in the real-life situation, and then possibly when it is already too late. Namely after an accident on the production floor with workers involved.

It is not actually necessary for things to reach this stage, however, because the applicable standards and guidelines of national and international regulations can – and should – already be taken into account at the planning stage.

Legal framework

Safety-relevant markings for workplaces and hazardous areas are governed by the international standard ISO 7010 “Graphical symbols – Safety colors and safety signs – Registered safety signs”. Further standards and directives serve as the basis for national rules and regulations.

In Europe, application of Directive 92/58/EEC “Minimum requirements for the provision of safety and/or health signs at work” is binding.

In Germany, the stipulations of the directive determine the contents of the Occupational Health and Safety Act (ArbSchG) and the Ordinance on Workplaces (ArbStättV), and are in turn reflected in concrete proposals for implementation in a series of Technical Rules for Workplaces (ASR). The following rules are here particularly relevant:

ASR A1.3: Safety and health protection markings

(BAuA – Technical Occupational Health and Safety (incl. Technical Rules) – ASR A1.3 Safety and health protection markings – Federal Institute for Occupational Safety and Health)

ASR A2.3: Escape routes and emergency exits, escape and rescue plans

(BAuA – Technical Occupational Health and Safety (incl. Technical Rules) – ASR A2.3 Escape routes and emergency exits, escape and rescue plans – Federal Institute for Occupational Safety and Health)

Particular importance is attached to the subject of signage in the aforementioned standards and guidelines. Floor markings, on the other hand, are somewhat neglected in my opinion. If we compare the situation in industry with that of road traffic, the differences in many companies are immediately evident. Road traffic safety places a strong emphasis on road markings. By contrast, the use of floor markings is far less widespread in many areas of industry.

Purpose of floor markings

The fact that floor markings are equally significant in industrial settings can be illustrated by taking a closer look at the following three aspects. Floor markings serve to

- safeguard occupational health and safety for workers

- maintain order around the workplace

- convey information

Work safety through floor markings

The issue of safeguarding occupational health and safety is obvious when viewed in the light of workplace accident statistics.

One of the most important points in this context is the separation of transport and walking routes in all areas of the factory, whether it’s an warehouse aisle, assembly, manufacturing area, or a packaging zone. It is not always possible to erect a physical barrier between the areas used by pedestrians and forklift trucks. An alternative could be to define unambiguous boundaries by way of corresponding floor markings.

Yellow stripes can be drawn using self-adhesive floor marking tape as a fast and simple solution. The important thing is to ensure sufficient contrast between the tape and the floor. Crossing points can also be marked with zebra tape to attract additional attention for the hazard. A more expensive, but at the same time more conspicuous and thus safer possibility is to paint the complete pedestrian route yellow (or green in the case of an escape route).

A further key point when it comes to occupational health and safety is the marking of stairs and landings. How often have you yourself tripped when using stairs? And do you always use the handrails? I, too, regularly forget, at least until the next time I trip. According to statistics published by the German Social Accident Insurance (Deutsche Gesetzliche Unfallversicherung, see table on page 9) in 2020, approximately one-third of fatal accidents in companies occur in the area of structural installations. Floors are in first place, followed directly by stairs. Markings at such points of a factory floor can help to remind workers of the potential hazards and thus save lives, of course. It is not imperative to mark every single step with paint or non-slip tape: A black-and-yellow marking on the first step or the edge of a landing would already increase visibility for workers.

Create better order through floor markings

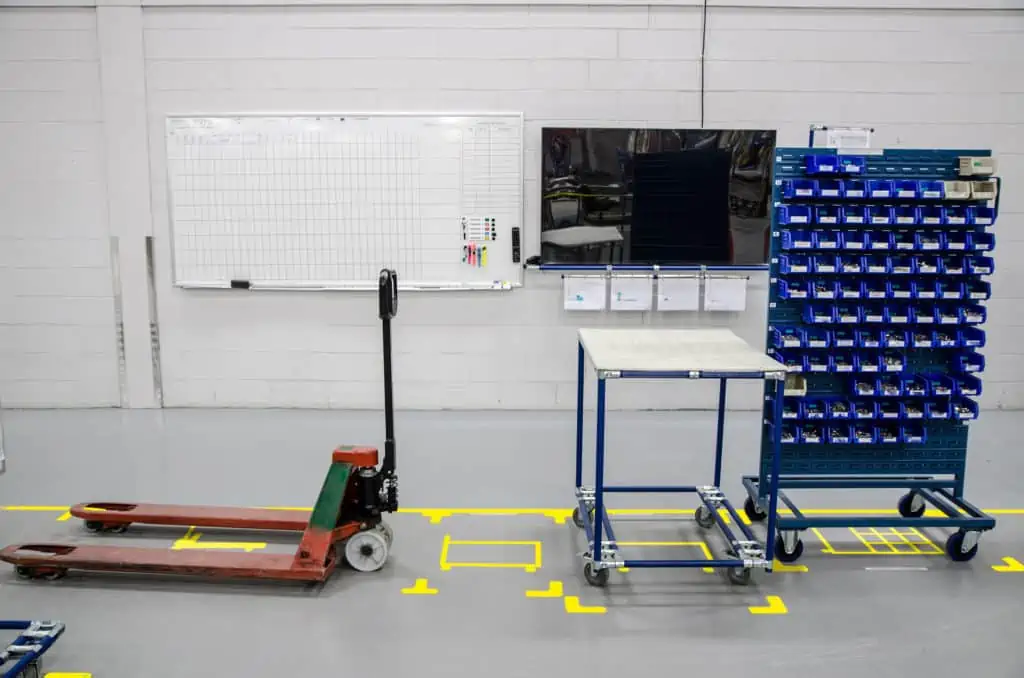

In addition to occupational health and safety, floor markings also play a decisive role in maintaining order around the workplace. I am sure that most readers will know the workplace organization method 5S, a principle of the Toyota production system. One essential aspect is that tools and equipment are assigned a specified and fixed location.

You have probably heard the saying: “Organized people are just too lazy to search.” But searches take time, and time is expensive. That starts with situations as trivial as needing a pallet truck to swap crates or boxes at your workplace. One of your workers needed the pallet truck for a job in the warehouse, and simply left it standing somewhere on the warehouse floor. That creates confusion and a long and expensive search for basic equipment. If the pallet truck is assigned a readily accessible location, on the other hand, every production worker knows exactly where it is to be found and then returned after use. Here, too, the use of simple, color-coded and self-adhesive floor marking tape results in more secure work processes.

Providing information through floor markings

The task of conveying information by way of relevant floor markings is naturally very closely related to the subjects of tidiness and occupational health and safety. Symbols and colors on the floor can be used to identify different areas, and are also readily understood by workers and visitors who do not speak the local language or are not familiar with your site.

Furthermore, organization in the manufacturing center can be made more transparent by marking staging and warehouse aisles accordingly. The areas for parts Works-in-Progress for machining could be marked in red, for example, while blue tape is used to designate areas for the finished parts. Red-and-white stripe markings are often used to define areas for parts that are currently blocked for machine processing. In this case, floor tape is used to mark the current process state of parts.

So you see, there is huge – and often still untapped – potential for the use of floor markings or floor tape. Before you start to seek out the corresponding potential in your own manufacturing environment, I would like to say a few important words about the color-coding and its meaning used for floor tape.

What do different colors mean?

ISO 7010 defines relevant symbols and safety colors. Generally speaking, the symbols and colors can be divided into the following five categories:

- Warnings (signal yellow, RAL 1003)

- Prohibition signs (signal red, RAL 3001)

- Fire safety (signal red, RAL 3001)

- Mandatory actions (signal blue, RAL 5005)

- Safe conditions (signal green, RAL 6032)

When planning floor markings, they should also reflect the specified colors (ISO 3864) and symbols for the individual categories.

When are you going to begin the planning and implementation of corresponding floor markings?

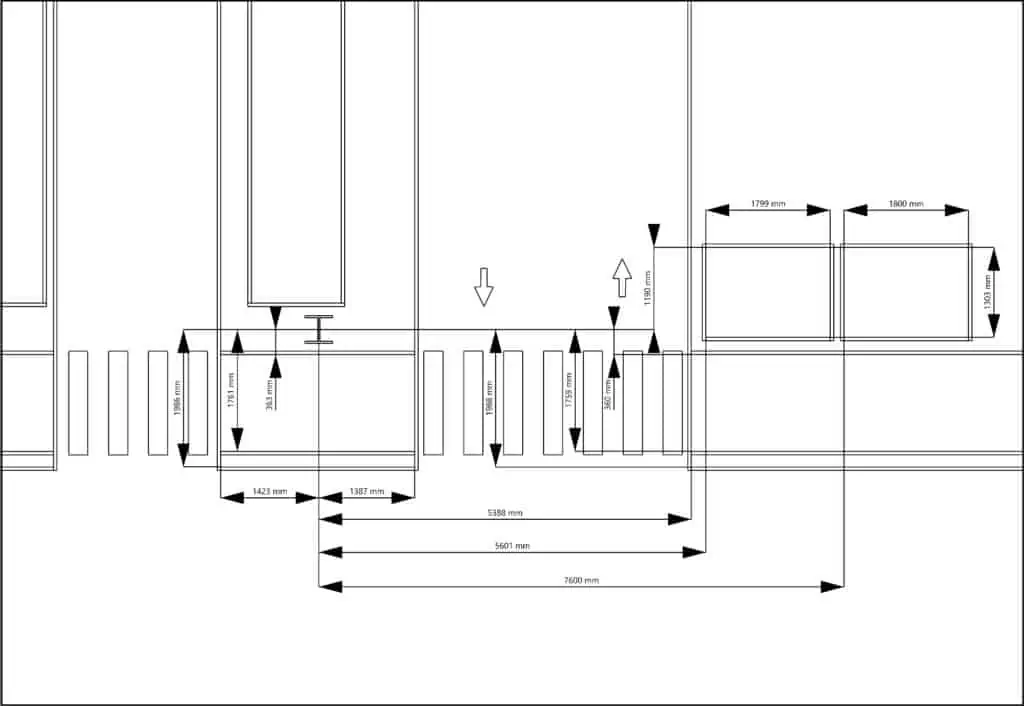

It is especially important that the various floor markings are already incorporated with appropriate dimensional information when planning the production floor layout. That will simplify realization when the plans are implemented. When choosing a material for the markings, long-life, walking-working floor markings for the facility floors are to be preferred to ensure that they also remain properly visible for a long time to come.

No problem, simply subscribe to our Blog-News!