This article shows the use of 3D models of STOPA long goods storage or cassette storage in the visTABLE® software. STOPA Anlagenbau GmbH is one of the leading manufacturers of space-saving, ultra-modern and automated storage solutions with a system. Long goods storage, as the name suggests, accommodates long material, usually in the form of bars, profiles, pipes, strip and rolled metal material. Warehouses in general can have a significant impact on the lead time and therefore also the delivery time of products. For this reason and also because of the corresponding space requirements, they are an important aspect in the layout planning of a factory.

Concept planning with STOPA LG-E standard configurations

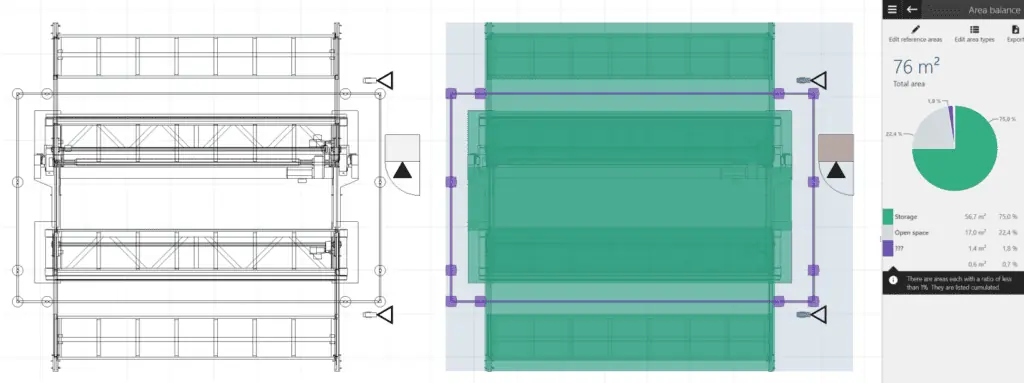

To use long goods storage in a visTABLE® layout, the software offers a “STOPA Long goods storage” catalog. which is very suitable for visualizing single-tower or two-tower configurations of the storage system as a concept both as a 2D drawing and in 3D.

Using the 3D models is extremely easy. Because the manufacturer’s typical configurations are already available as modules in the model catalog, they can be placed in the layout using drag and drop. This allows, among other things, the installation area, height, control points, storage and retrieval and safety distance to be mapped:

Flexibly adapt the layout of storage modules

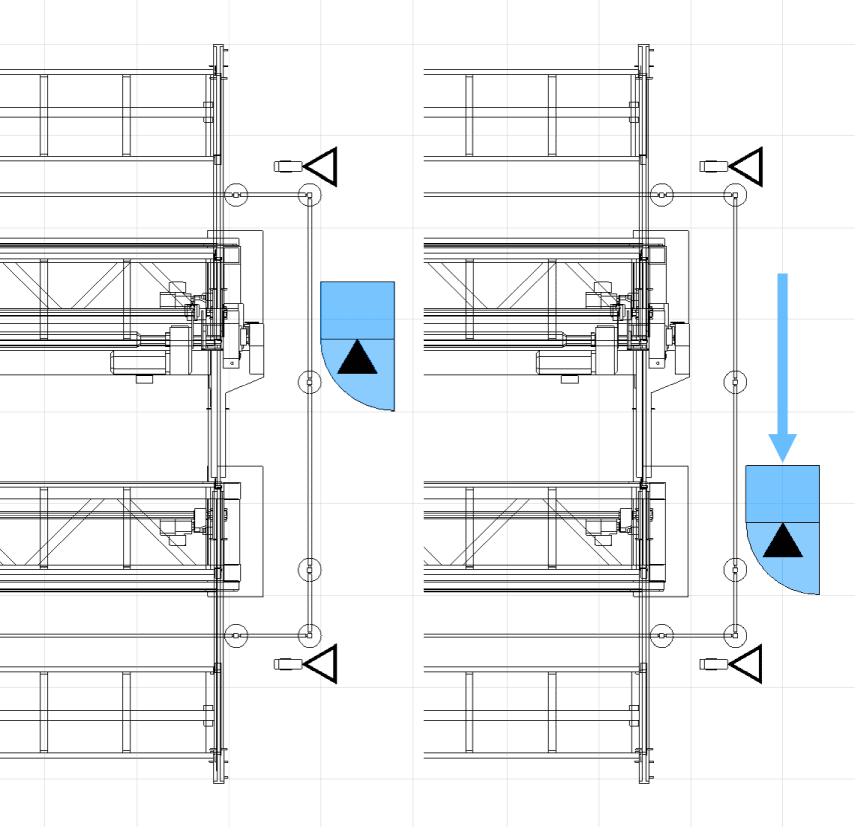

The modules can be partially adapted; control points or fences can be moved, for example.

Storage towers can be scaled in height, although this only makes sense within the heights offered by the manufacturer of 3m to approx. 8m. The storage capacity based on the number of cassettes used can also be made visible in 3D using the bulk function. This means that the configurations can be adapted to the current use case. The feasibility of the 3D concepts must always be coordinated with the manufacturer STOPA in the final step of the implementation planning, as this involves further technical requirements in detail that only the manufacturer can answer.

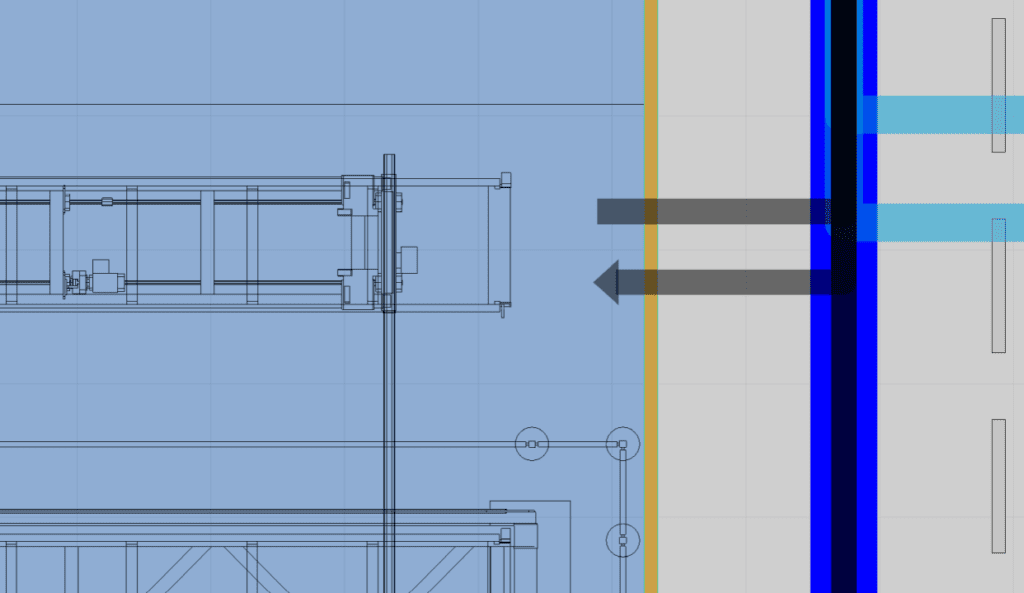

Integration of long goods storage into the material flow

In addition to the important space requirement parameter, the visTABLE® software also enables the visualization and evaluation of warehouses with regard to material flow. For example, the direct connection to machines for further processing of long goods can be analyzed, as can the higher-level supply from a central warehouse. This allows the optimal integration of the long goods storage systems into production to be validated with the most direct access to material possible and transport of the long goods in the shortest possible time is guaranteed.

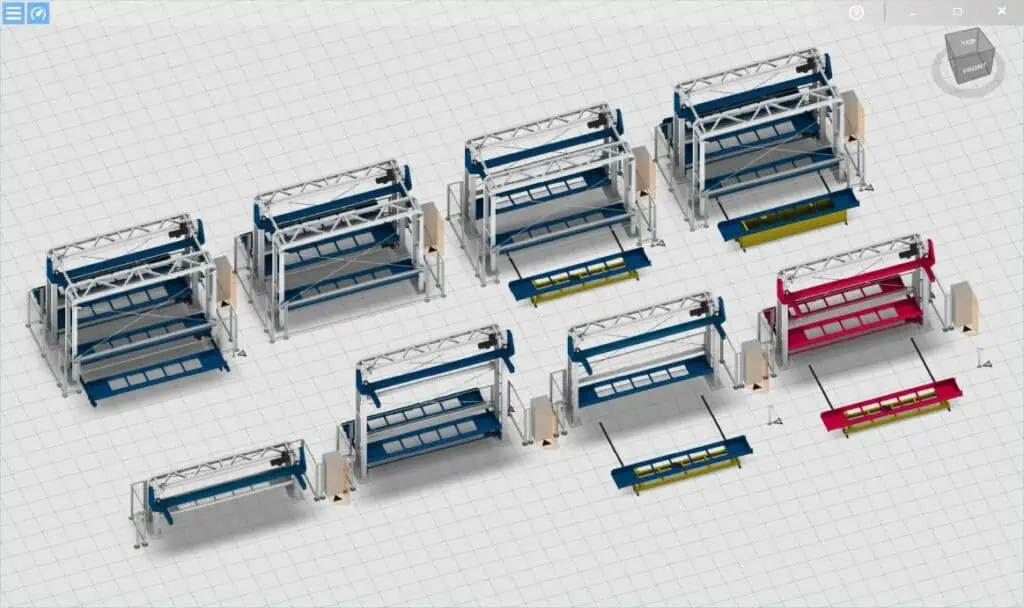

Which versions of the STOPA long goods storage are available in the visTABLE® model library?

4 single tower and 4 double tower variants are offered in different heights. These also differ in the type of transport used for storage and retrieval. There are variants with and without chain conveyors and transport trolleys, and the latter with and without excavation.

Advantages for suppliers and equipment suppliers when using their products in planning with visTABLE®

For suppliers like STOPA Anlagenbau GmbH, there is a double benefit because products are available in visTABLE®. On the one hand, the factory operator plans with specific company products in the early phases of factory planning. This also increases the likelihood that customers will use these products later. On the other hand, this also speeds up the implementation planning in a later phase, as customers already go into the implementation planning with concrete concepts, i.e. a 3D layout. For suppliers, these 3D concepts can then be opened in the free visTABLE®Viewer in order to use the customer layout as the basis for a concrete offer. The uncomplicated entry into the software and the understandable 3D visualization are the basis for effectively exchanging important information between suppliers and factory operators.

No problem, simply subscribe to our Blog-News!