When AI turns images into 3D models – opportunity or risk for factory planners?

KI tools, like Meshy, generate impressive 3D models from simple images in just a few minutes. Sounds like a revolution in factory planning – and it is, at least to some extent. The article explains how Meshy works, where its strengths lie, and why planners should still remain cautious – because realistic does not mean dimensionally accurate.

What is Meshy actually?

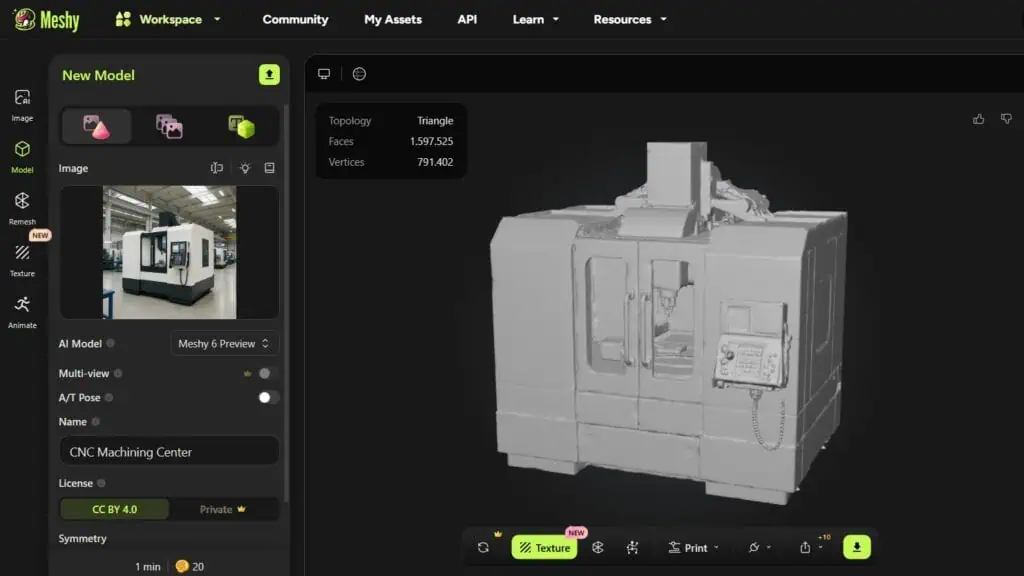

Meshy is an AI tool that is currently making waves in the 3D world. The twist is: From a simple image – whether a photo or an illustration – a 3D model is automatically generated, including texture and optimized geometry. The whole process works at the push of a button and often takes only a few minutes.

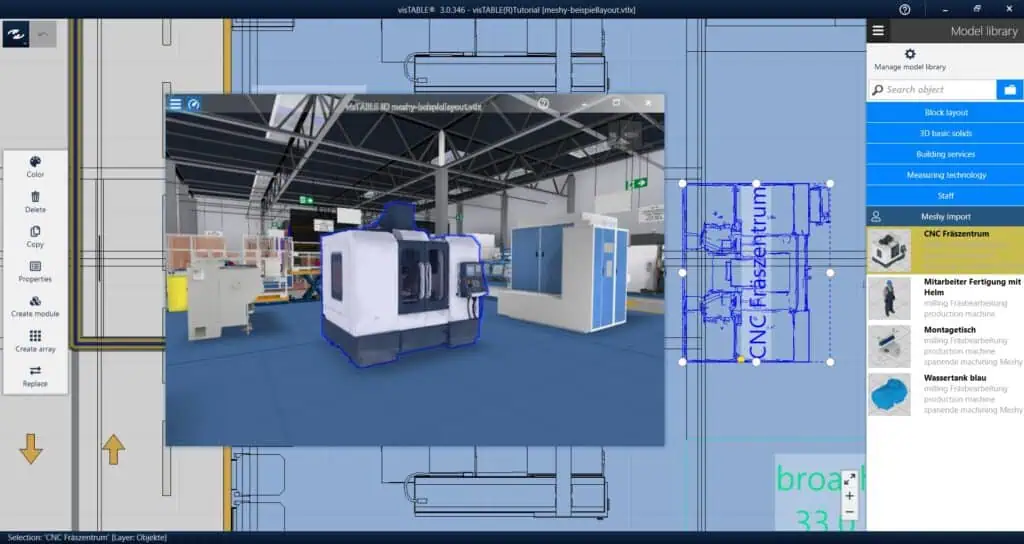

The result looks astonishingly realistic: A textured, lightweight model that can be seamlessly integrated into real-time environments, such as visTABLE®, Unity, or Blender. For factory planners, this sounds almost too good to be true – and in a way, it is.

How does Meshy work?

The workflow is incredibly simple:

- Select mode: Select “Image to 3D”.

- Upload image: Drag and drop into the designated area.

- Generate model: Meshy analyzes the image, recognizes the object, and generates a first 3D model.

It usually only takes a minute. The first result is a gray, highly detailed geometric model. After that, a texture can be calculated to make the model look more realistic – this step takes a bit longer, but it is visually worthwhile.

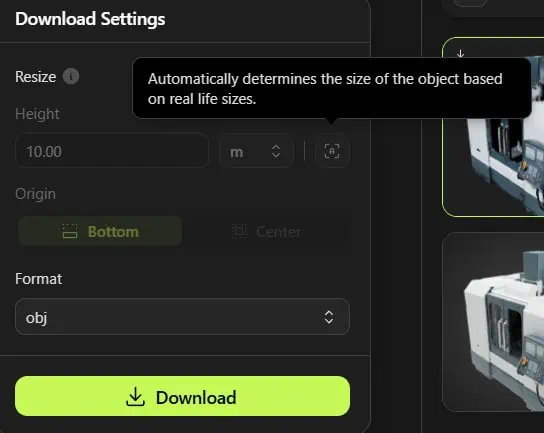

In the final step, the model can be adjusted in terms of resolution. Depending on your needs, you can choose between ‘Low’, ‘Medium’, ‘High’, or ‘Ultra’ – or specify a target polygon count to optimize the model for real-time environments. The texture is preserved, but the model itself becomes noticeably slimmer.

When exporting, you can even specify a real height or have it estimated. However, the estimation function is – like so often with AI – sometimes surprisingly accurate, sometimes completely off.

Example: Meshy models in visTABLE®

For a first conceptual draft in factory planning, the whole thing is quite impressive. A realistic model of a machine or assembly table can be created in seconds and inserted into visTABLE®. The result: a tangible, visual concept of a future production facility.

But this is precisely where one should be careful. Meshy only generates what it sees – or rather, what the AI believes it has seen. Invisible backsides or hidden areas are simply mirrored symmetrically or ‘guessed’. And in practice, this quickly leads to problems: Machines are rarely symmetrical. Controls, connections or units are usually only on one side.

Such a ‘guessed’ model may look correct visually, but be completely wrong functionally. Relying on this to make actual layout decisions carries the risk of planning errors – which can be expensive.

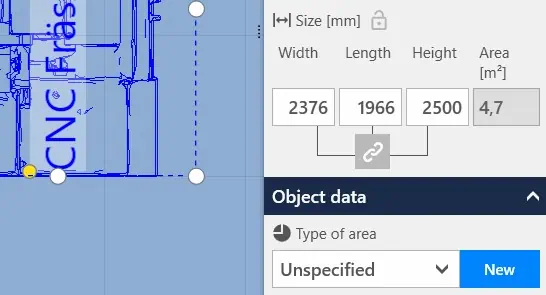

At least the dimensions of the 3D model can still be adjusted during import or later in the layout provided that the actual dimensions are known. Below are the model properties, allowing adjustments to width, length, and height in visTABLE®.

Here are some more examples of placeholder models in visTABLE®:

Meshy: Stylish looks, fuzzy details

The conclusion at this point: Meshy delivers impressive results to the eye, but not to the caliper. The generated models are not CAD models. They do not claim to be to scale, contain estimated proportions, and lack certain details.

If used uncritically in planning software, they can quickly create a deceptive impression of precision. Therefore, Meshy is ideal for initial visualizations, concept sketches or communication purposes – but not for technical planning. Moreover, the models are also topologically questionable, meaning that the surface quality is rather poor upon closer inspection, for example in VR, and a 2D derivative (see image example below) does not allow for a clean line representation in the layout. A highly convincing 3D illusion emerges, even from just a few meters away, depending on the export resolution, thanks to the realistic color details of the models.

Conclusion: AI can serve as a creative tool, but is not suitable as a planning tool

Meshy is a fascinating example of the speed at which AI tools are transforming the 3D world. Where CAD models used to be painstakingly created or simple blocks were used, today realistically looking factory environments can be generated in minutes. This is extremely helpful for conveying a vision to stakeholders in the early planning stages and for initiating discussions.

But – and this is crucial: Realism is not the same as reality. Meshy can show what an idea looks like, but not how it needs to be built.

Therefore, planners should take certain guidelines into account:

- Use only within clearly defined limits: Restricted to the concept and communication phases.

- Create transparency: All parties must know that these are inaccurate models.

- Update CAD data: As soon as exact dimensions are available, be sure to replace them.

- Check dimensional accuracy: Do not make decisions about areas, paths or collisions based on Meshy models.

When used effectively, Meshy supercharges creativity in the early stages of factory planning. If used incorrectly, it quickly becomes a risk factor.

AI is playing an ever-growing role in factory planning by enhancing human creativity – yet it remains precisely that: a tool of support. The responsibility for planning still lies with humans.

By the way, Meshy is just one of many tools currently offering AI-based 3D generation. It is worth testing alternatives as well – for example, Manex3D that offers similar features, in some cases even for free. Suitable model formats can be written using Convert 3D. In the rapidly expanding field of AI-assisted model generation, innovative solutions are constantly emerging, opening up exciting possibilities for factory planners.

Related topics:

3D visualization as a thinking tool within the company

5 Methods for 3D modeling of equipment for layout planning

Photogrammetry or photo modeling for the digital factory model?