Maschinenfabrik Bernard KRONE GmbH & Co. KG acts under the roof of the KRONE Group. KRONE produces innovative and powerful forage machines at its location Spelle (Germany). The product portfolio comprises disc mowers, rotary tedders, rotary rakes, forage wagons, large square balers, round balers, pellet harvesters, and the two self-propelled mowers BiG M (high-performance mower conditioner) and BiG X (forage harvester). KRONE counts more than 6,100 employees throughout the world who generated a sales turnover of nearly 3.2 billion euros in the last year.

“Thanks to the planning in visTABLE®, our layout planning considerably gained in quality”.

Jens Gravemann (Plant Manager)

Elaboration of the planning guide

Krone was faced with the challenge to elaborate a digital planning guide for the planning tasks still to be done. The use of the production buildings with a few of them reach in tradition changed over the last years which was also the reason why up-to-date and valid ground plans for buildings and production layouts were not always available completely. That’s why it was decided to create digital plans and models of the whole plot of land.

The building plans were created by way of 3D-reverse engineering by digitizing already existing objects with a 3D scanner and remodeling with CAD software.

The elaboration of the digital factory model was supported by Bross Consulting GmbH. Bross as a logistics and factory planner supports its customers in all phases of planning and implementation. Initially, Bross coordinated the aerial photogrammetry of the plant by way of a drone. The resulting orthophotos were used to produce both a 3D model of the building shell and true-to-size 2D plans. Subsequently, one building after the other was gauged by way of a terrestrial 3D laser scanner. The resulting point clouds were remodeled, with the result of a digital factory model of all production buildings.

Why the software visTABLE®?

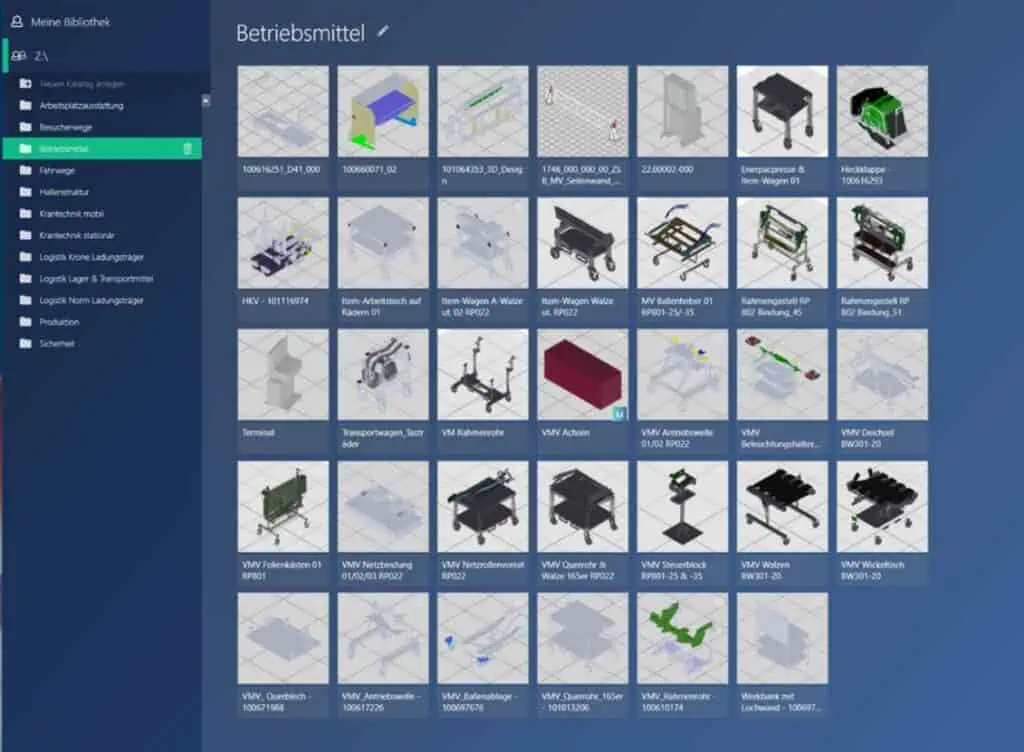

After the true-to-size plans and models required for the planning guide have been created, different solutions for layout planning were discussed. visTABLE® revealed to be the most suitable solution because it was possible to import the generated plans as DWG or PDF files and the models (e.g., STEP or AutoCAD) without undue problems. In addition, visTABLE® possesses a very large and constantly growing logistics equipment/machinery library. This was a real advantage because, thanks to scanning, only the building, including its technical equipment, existed, but not the machines, workplaces etc. Modeling of these workplaces etc. would have taken much more time and money. Instead, it was considerably more efficient to drag the systems from the visTABLE® layout library and drop in the layout.

In addition to the aforementioned essential advantages, there were further reasons speaking in favor of visTABLE® and being of importance in particular, for the subsequent rollout.

“The comprehensive manufacturing equipment library and the intuitive operation of visTABLE® considerably facilitate the layout planning.”

Alexander Follath (Bross Consulting GmbH)

Successful introduction of visTABLE®

One of the reasons why layouts have not always been up to date were missing of a central management, of a versioning and a layout library. As a response, a library has been set up which is linked in visTABLE® by all planners. In combination with Microsoft Sharepoint that operates as a central storage location for all layouts and possesses an integrated function for versioning and management of the documents, there are no data silos for the individual departments, no data inconsistency, and no different storage locations.

The aforementioned models of the visTABLE® library are used for layout planning. In addition, special load carriers, fixtures, manufacturing equipment, and products from the construction department are imported. The 3D models supplied from the construction department are often too complex and too rich in details as to be able to be used in factory planning. When importing the models, visTABLE®Object Manager checks the models and visualizes by way of a traffic light indicator whether or not the models are to be reduced prior to importing them.

Another advantage of visTABLE® is that its layer structure and area types can be configured individually. This enables interdisciplinary cooperation of visTABLE® with system planners, for example, but also with the construction department, allowing everybody to create a relevant structure for his own department.

No problem, simply subscribe to our Blog-News!