With this conviction “THERE IS AN EVEN BETTER IN EVERY COMPANY” Staufen AG has been advising and qualifying companies and employees worldwide for 25 years. Staufen helps to get the right changes off the ground quickly and focuses not only on process excellence but also on leadership excellence. Because a lively and sustainable change culture can only be established together with managers and employees.

- 320 employees

- 13 locations worldwide

- 65 Mio. € revenue (2018)

Services of Staufen AG in factory planning:

- Potential analysis

- Factory structure planning

- Detailed and detailed planning

- Project Management

Together with customers to value stream oriented factories with visTABLE®

As early as 2006 Staufen AG recognized the potential behind visTABLE® for planning factory concepts and factory structures according to the principles of lean production. At Staufen, great importance is attached to the seamless integration of all participants in the planning process, from the initial idea to the completion of the design.

visTABLE®touch is unbeatable in terms of operation! The software is easy and intuitive to use. Customers appreciate the comprehensible visualization of the developed factory concepts. The software follows our practical experience.

– M. Feldmeth, Project Manager, Staufen AG

For this planning philosophy, tools are needed that allow the active participation of all parties in the planning process. Acceptance is only created when all participants from different functions are informed about the progress, understand what is being planned and can contribute their process knowledge to the solution finding process. The principle of “bringing everyone to the table” is a basic idea of visTABLE® and is exemplified at Staufen. In terms of employee qualifications, the consulting company also benefits from the steep learning curve with the software. Internal trainings with consulting support from plavis GmbH enable structured employee qualification and high flexibility in employee deployment.

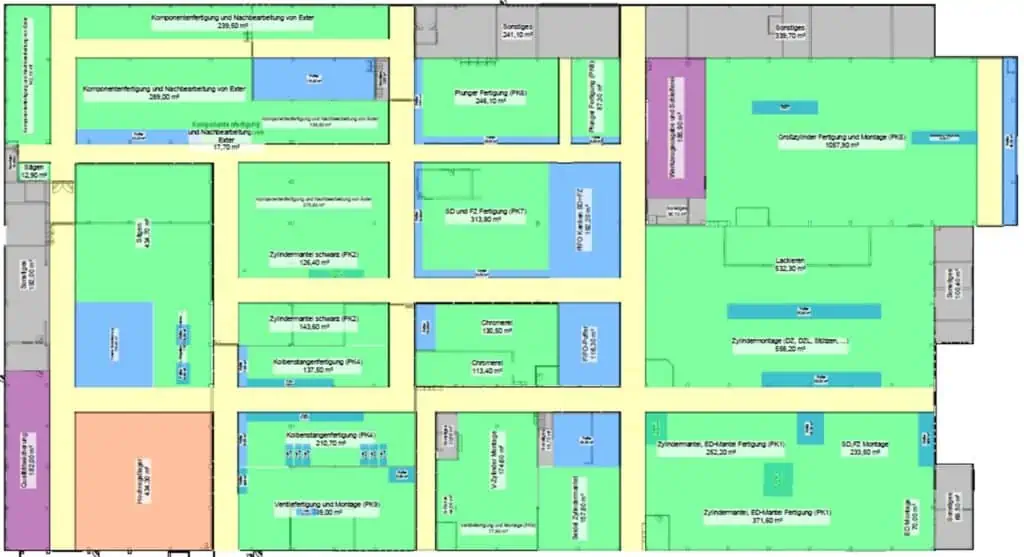

Customized planning for the factory layout

From coarse to fine

Different project budgets, planning goals and planning times pose challenges for a planning solution. Due to changed framework conditions and new findings in the planning process, factory planning projects often require that changes can be incorporated and evaluated ad hoc at any time, regardless of the respective planning maturity level. visTABLE®touch supports this approach with flexible, customized planning functions, whether simplified block layout or detailed area display. The focus is always on the value streams of the company.

With visTABLE® we can work very quickly and flexibly.

– M. Feldmeth, Project Manager, Staufen AG

The high planning speed improves the efficiency of the planning process. In addition, the degree of planning maturity and planning reliability also increase. Much more variants can be considered and evaluated with key figures in the same time. In addition to operative logistics key figures, the planning result is also evaluated in monetary terms. This results in an optimally designed factory layout. In the end, what counts are long-term cost savings in the factory due to low transport costs and shortest transport routes.

“Software doesn’t have to do everything.” Staufen AG has made this experience in comparison with other software

– M. Feldmeth, Project Manager, Staufen AG

This is because as the range of functions increases, which is only used very rarely, complexity increases and there is a strong bond with individual software experts, which severely restricts flexible use in a team. It is more important that employees are qualified as quickly as possible, as this is largely responsible for the success of a project. The integration of new employees succeeds in a very short time due to the simple operation and user interface as well as the comprehensible visualization in visTABLE®touch. This ensures a safe and efficient use of the software in factory planning projects.

The customer at the center of all efforts

Even in the early stages of planning, Staufen aims to involve participants from all areas and later phases. Whether it is the architect, works council, local employees or master craftsmen, convincing visualization can create a high level of acceptance and planning security at an early stage. Staufen AG has found that visualization in visTABLE®touch also integrates participants from other fields without a technical background into the planning process, thus adding value. This means that requirements are communicated at an early stage, e.g. concerning buildings, occupational safety or workplace design. The planner then takes these into account more quickly in the layout or planning solution. All parties involved feel respected and understood, a recipe for success for long-term satisfied business relationships.

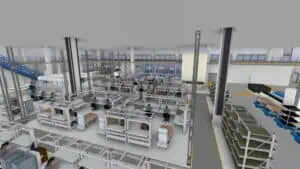

visTABLE®touch combines both, a simplified 2D representation and a clear 3D view in one software. This enables a comprehensible visualization for all participants at the push of a button.

Often the imagination is lacking in 2D and with the integrated 3D view we directly map worker and movement space or swivel rooms. The reference to the real factory is ensured for all participants at all times.

– M. Feldmeth, Project Manager, Staufen AG

Acceptance thus increases considerably with the depiction of a 3D installation plan. At the same time, however, it is also necessary to clearly display and evaluate certain planning functions such as material flow and area in a “map” of the factory, the layout. visTABLE®touch combines both and thus offers the planner and the customer the best of both worlds.

Flexible in the project business

Each project is different in terms of available budgets, customer goals, planning object, scope and input data.

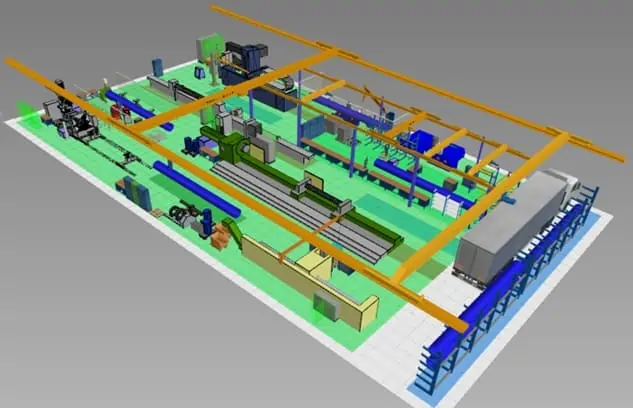

With visTABLE®touch we act according to project focus and planning maturity, whether it is a rough block layout for plant structure planning or the 3D layout plan of an optimized assembly line.

– M. Feldmeth, Project Manager bei der Staufen AG

Even with little or fuzzy data, planning can be done in visTABLE®touch. A comprehensive model library with more than 1,400 3D objects enables comprehensible visualization of factory concepts even in early phases and CAD data of customer-specific machines can be read in at any time via the easy-to-use ObjectManager.

The touch-optimized user interface provides intuitive access to a professional planning system. In no time at all, processes can be documented as a value stream oriented representation and used as the basis for a subsequent layout evaluation at the push of a button.