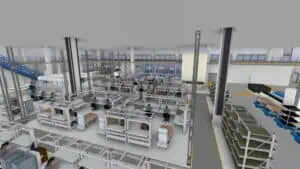

The Fraunhofer Institute for Industrial Engineering successfully uses visTABLE® products from plavis GmbH for team-based 3D factory planning to be able to plan value-added assembly processes as quickly as possible.

To simplify production and logistics processes, the know-how of employees from assembly, logistics, and production planning/control is required. For this reason, a project team – consisting of employees from these areas – was formed. This allows the team to check and rapidly coordinate the feasibility of optimization proposals in short control loops, and to jointly make prompt decisions on the practicability of implementation.

“visTABLE® hardware and software provides all planning participants with an easy-to-grasp visual representation.”

The provision of information to all team members is crucial to rapid project progress. The visualization of planning stages is a decisive factor for the involvement of operational staff, who often have little time for processing preliminary information in addition to conducting ongoing business. On the one hand, visualization by visTABLE® software makes the information essential for planning immediately available to all those involved. On the other hand, suggested changes can be incorporated, visualized, and validated immediately.

The focus of the planning was on the optimal design of different individual workstations and the overall arrangement of the workstations in line with logistics requirements. Other requirements that had to be considered required the expertise of the entire planning team. In the team meetings, for example, logistical or production-related boundary conditions such as the necessary dust and transport protection packaging and compliance with 24-hour gluing times could be immediately considered in the planning. A specific assembly planning methodology from IAO was used to organize the project flow.

“Alternatives can be created and compared quickly.”

Variant comparison

The visTABLE® planning tool was used so that the entire team could find out about the current stage of planning and decide on optimization proposals and alternatives. It provides all those involved in the planning process with an easy-to-understand visual representation and – compared with a purely 2D representation – allows them to focus on the essential planning aspects. This largely eliminates abstraction of how the 2D layout might look in reality. In this case – in contrast to using the 2D layout – variants were able to be assessed very quickly to achieve a spatially flexible arrangement of the assembly stations.

Space optimization

The objective was to reduce the required floor space compared to the current space requirements and to avoid obstructions to employees caused by constricted space. In this context, visTABLE® proved to be highly suitable for the development and selection of planning variants in the case of two separately developed workstation concepts for pre-assembly and final assembly. Non-target layout alternatives could be identified equally well in the 3D layout as in the real workstation layout. In the 2D layout, on the other hand, existing deficits were not recognizable.

Prof. Dieter Spath,

Dipl.-Ing. Oliver Scholtz

Fraunhofer Institut für Arbeitswirtschaft und Organisation IAO

Nobelstr. 12, D-70569 Stuttgart