Software for assembly planning

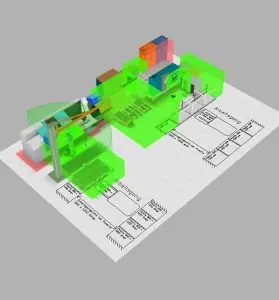

- Create assembly plans

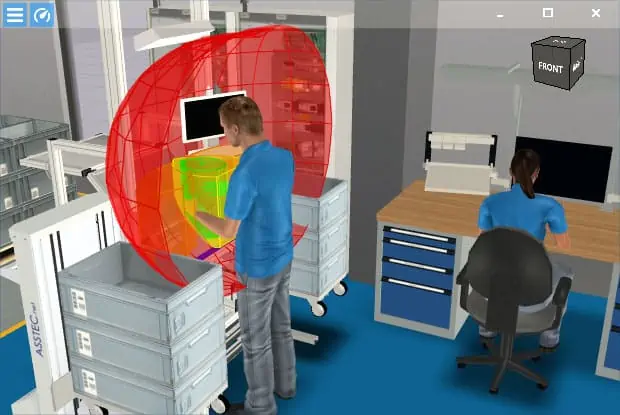

- Design workstations

- Provide materials

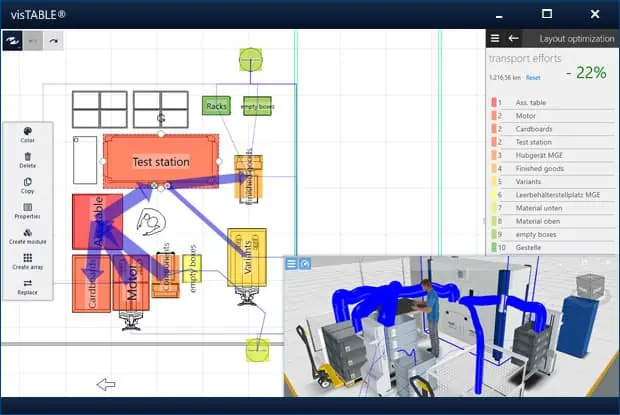

- Minimize walking distances

- Digital map processes

- Compare variants

Assembly is the heart of production and at the same time one of the biggest cost drivers when it’s not optimally planned. Long walking distances, poor line balancing, or poorly designed workstations quickly lead to inefficiency. The visTABLE® software solution supports users in assembly line planning, workstation design, and planning of material supply in the manufacturing industry. Using this software system, assembly planning is absolutely intuitive. So your work gets results much faster than in CAD software.

With visTABLE®, you can digitalize your assembly planning — from the assembly line and workstation design to the static simulation of complete processes.