Assembly planning software

- Assembly workplace design

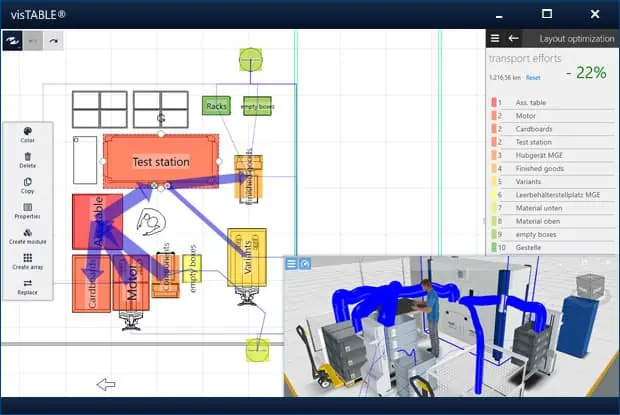

- Assembly line planning

- Material supply

- Optimize walkways

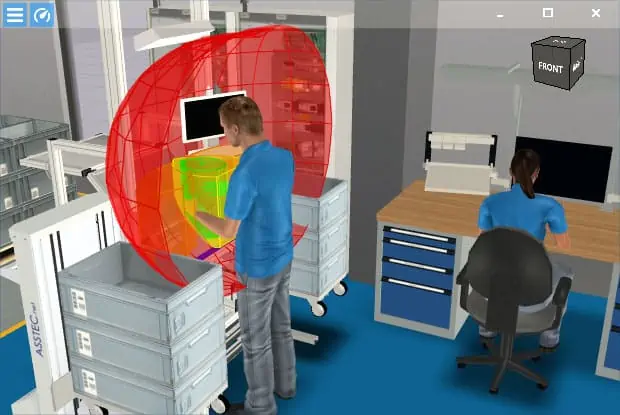

- Ergonomics

- Standardization

The visTABLE® software solution supports users in assembly line planning, workstation design, and planning of material supply in the manufacturing industry. Using this software system, assembly planning is absolutely intuitive. So your work gets results much faster than in CAD software.