Securing company-wide acceptance for the 2025 factory expansion

The practical planning details all need to be correct, of course. But internal communication and acceptance of the planning concept is no less important for the planning team at SILOKING. The biggest factory expansion to date is to be realized between now and 2025, and that promises to be a major challenge for the company’s 480-strong workforce. The current production space is to be increased from 5,900 m² to 13,800 m². Buildings, technologies, equipment and processes will all be changing, as will the immediate work environment for many of the employees.

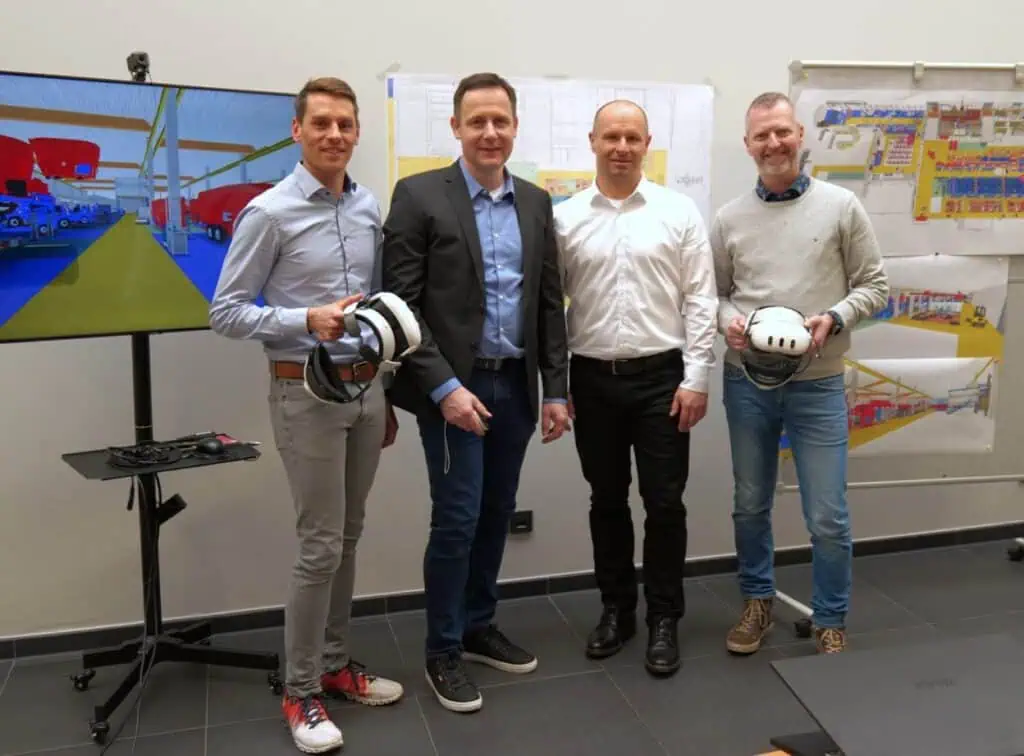

The planning team produced a full 3D model of the new factory in visTABLE® and in this way created an ideal basis for their internal employee workshops. One such workshop was organized in Tittmoning on March 7th, 2024, firstly to inform everyone involved on the current status of the planning, and secondly to promote an exchange of ideas. The chosen tool was the VR view in visTABLE®, and that was applauded as a resounding success by everyone who took part in the workshop.

“It is great to obtain a direct impression of the dimensions of the future factory!”

Philipp Altenbuchner – SILOKING

As a customer with active maintenance or subscription, you can try VR here:

SILOKING – market leader for innovative feeding technologies

SILOKING Mayer Maschinenbau GmbH is a growth-oriented, owner-managed family company based in Tittmoning in Bavaria. It manufactures feed mixing machinery for customers in more than 50 countries, where its products are instantly recognizable thanks to their distinctive red and blue livery. Due to their considerable dimensions, however, the mixing and metering machines take up a lot of space in the production and assembly center.

Despite a certain standardization, the product portfolio still embraces a large number of variants, as SILOKING responds specifically to the individual circumstances of its customers, for example the size of their company, the types of feeds to be handled and the intensity of machine use. From welding of the feed containers, via painting and assembly through to quality control, therefore, the company operates with a high proportion of in-house manufacturing processes.

VR workshop with a virtual factory tour and discussion of the individual areas

SILOKING set aside a whole day to enable around two dozen participants from different departments to experience a virtual tour of their future company. At 30-minute intervals, pairs of employees from the logistics, manufacturing, assembly, procurement, administration and planning departments – as well as company owners Margit and Georg Mayer – were welcomed to the prepared VR stations. Philipp Altenbuchner and his colleague Norbert Stratmann explained the planning concept briefly by way of printed 3D views from visTABLE®, and plavis showed the participants how the VR technology functioned.

“I can now imagine everything much better, and especially how spacious it will all be!”

A participant

Each participant then donned the VR headset to move around the planned factory independently, while the colleagues from the planning team explained their ideas for the individual areas. The production department employees, for example, were able to head straight to the parts of the factory most relevant to their work, and could ask the various questions on their minds. Lively discussions ensued between the planners and the employees affected by their changes. SILOKING had clearly opted for an ideal participative approach. The planning team was also able to take away a few ideas for the next change loop, for example reappraisal of the floor space assigned to certain workplaces, modifications to the logistics processes or additional demands to be met by the workplace infrastructure.

At the end of the day, the participants spoke enthusiastically about the detailed 3D modeling of the planning concept, and in particular about the spatial impressions gained through VR.

The underlying technology

As recently as 10 years ago, virtual reality was still a barely accessible and moreover extremely expensive investment for smaller and even mid-size companies. Since 2016, however, VR has experienced a veritable boom in terms of technical development. The result is a choice of relatively affordable devices, with wireless VR headsets combining good image quality with mobility. In the case described here, two Meta Quest 3 headsets were linked up with two high-performance 16-inch notebooks with RTX 4090/4080 GPUs. This setup enabled the practically latency-free visualization of approx. 5 GB of CAD data, or – to put it another way – a 3D layout with almost 70 million surfaces. A Wi-Fi 6 router handled streaming of the visTABLE® VR imagery to the two headsets. The price tag for the whole equipment was around 10,000 EUR.

Would you like to try out visTABLE® to get an overview of the software?