Software for Factory Planning

- Construction or expansion of a factory

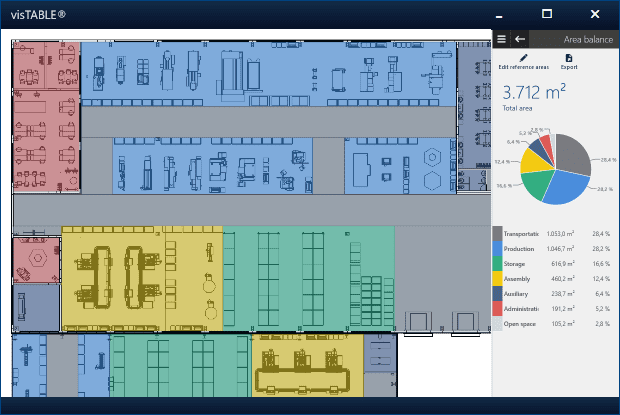

- Material flow analysis

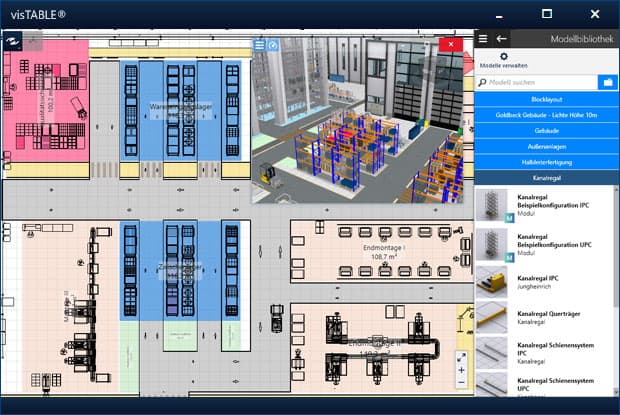

- Facility planning with 2D and 3D layouts

- Planning of new products

With visTABLE®, you can design your factory intuitively and efficiently. Our factory planning software supports you in creating 2D and 3D layouts, block layouts, material flow analyses, and walkway plans. Instead of spending time on tedious planning in complex CAD systems, you work with a straightforward and practical solution designed for real-world factory planning.