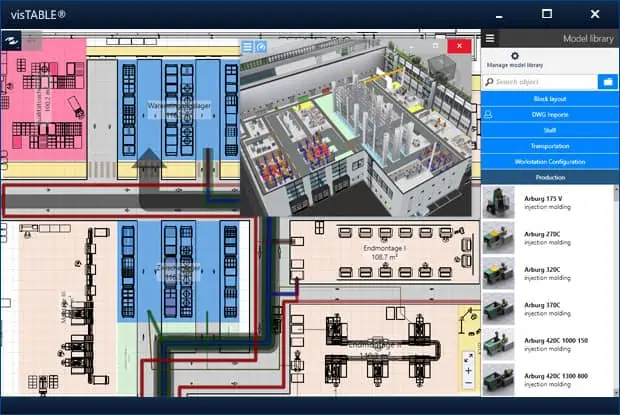

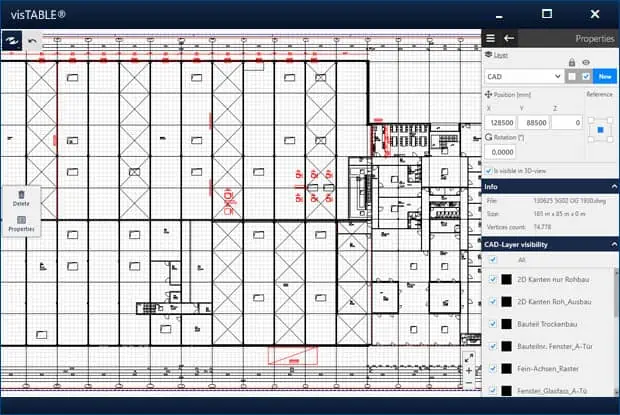

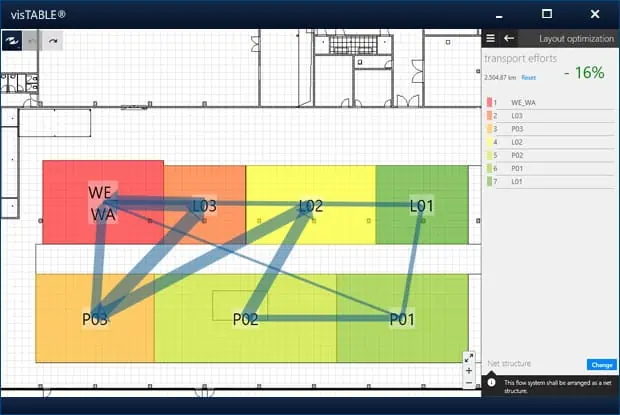

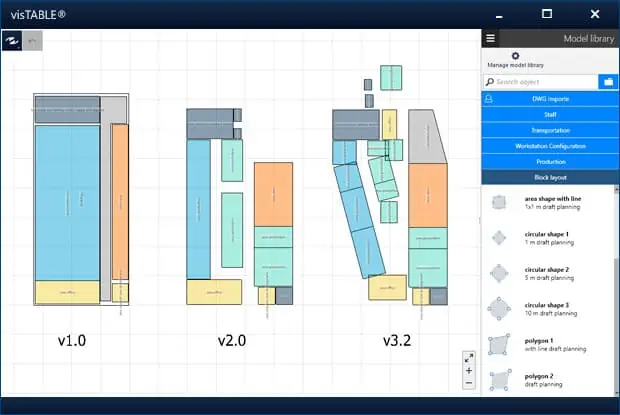

Factory layout design software

- Design a new plant site

- Extension of existing plant

- Factory planning & design

- Planning for new products

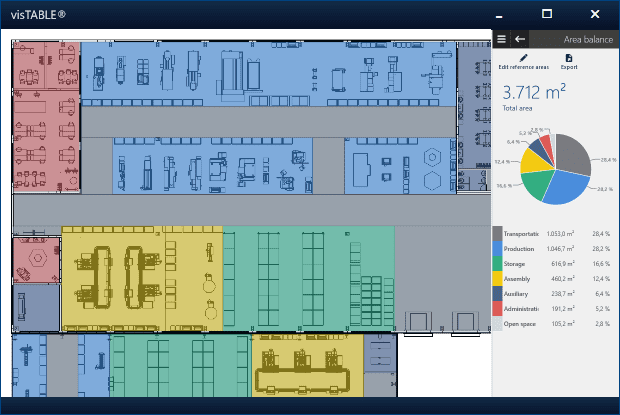

Design your factory layout with visTABLE® software – easy and quick. The software turns you into an expert in factory design, 2D/3D factory model and material flow analysis.