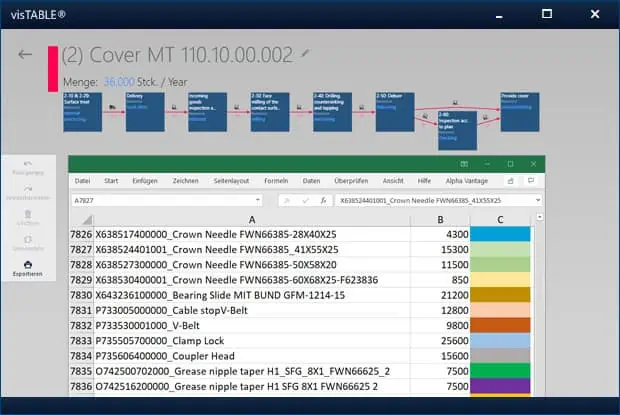

Value Stream Mapping Software

- Value Stream Analysis

- Identify Waste and Flow

- Production according to Pull Principles

- Value Stream Design

- Lean Management

- From Value Stream to Layout

With the value stream analysis software visTABLE®, you illustrate your company’s logistics processes according to lean criteria. Through digital value stream mapping, you gain information for optimizing your production. Eliminate waste, reduce lead time, define the future state value stream, and increase efficiency in production and logistics.