The block layout is the linchpin in layout planning for production sites. This is all the more true when it comes to improving the factory structure. This is because the rough representation of the functional areas of a factory and facilities in blocks provides essential information on the optimal arrangement of the operating resources and space already in the early planning phases of a project. This does not require detailed knowledge of the geometry of the machines, systems or assembly stations. It is sufficient to roughly determine their space requirements for equipment and to plan them as usually rectangular blocks to scale in the available space. The use of blocks can happen within an existing building or industrial facility, or as greenfield design with a defined footprint. Eventually, it will then represent a first very rough plant layout with equipment summarized and represented as blocks.

Logistics is also abstracted in the block layout. One calculates the intensities of the material flow and creates a Sankey diagram from it. The sources and sinks of the diagram are the block layout objects. As a result, the dependencies of the blocks to each other can be visualized very well by the strength of the material flow connections in a plan. On this basis, a systematic layout planning for the factory can start. Possible bottlenecks can thus be made visible already at this early stage in the factory layout or facility layout. The following video illustrates the procedure and explains how the material flow intensity for layout planning is determined.

Using block layouts for preliminary design of a factory building

One goal of factory planning planning is to produce assessable production or factory design concepts at a relatively early stage. These are always reflected in layouts, whereby one proceeds from the rough to the fine. The block layout serves here as a rough layout. The VDI Guideline 5200 on factory planning describes the rough layout as a result of concept planning, the third of a total of seven planning phases that are named as core elements in this guideline. Block layouts are created in variants, which are required, for example, for the preliminary design of the factory buildings. The next video illustrates the procedure using this example.

Current state vs. target state with a block layout

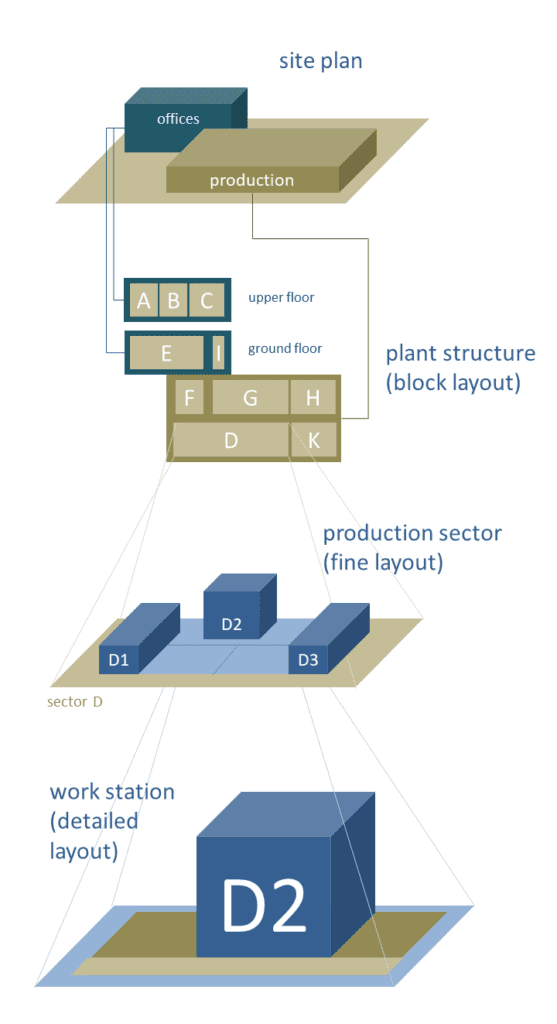

Block or rough layouts therefore regularly represent target states in layout planning. Existing productions, on the other hand, are more often designed only as a detailed layout with concrete models of the operating equipment in the actual situation (e.g. as an equipment layout plan). Nevertheless, it makes sense to also store the current state of a factory as a block layout. For this purpose, non-spatially separable resources (e.g. machine groups, assembly lines) and logistical units (e.g. warehouses, storage areas) are grouped into blocks. Their incoming and outgoing material flows are aggregated. This method results in a hierarchical factory layout. The top hierarchical level (plant layout structure) is the block layout of the production, warehouse, social and administrative areas.

The aim of such modeling is to have a “playground” available for layout planning at plant layout structure level, even for existing production sites or buildings. It is needed when the need for action in the direction of factory planning arises from the operational factory business. It is tedious and often time-critical to have to acquire the information on the block layout only at the moment of such a planning impulse. Therefore it is better to have already done this step. It is best to continuously check the block layout, even if only seemingly small changes have been made in the spatial arrangement of the operating equipment. In addition, the result is a master layout design that is always up to date. This also is the basis for any strategic consideration of change steps and perspectives for transformation.

Conclusion

On closer inspection, the block layout turns out to be a quite universal aid in layout planning for production sites. Not only does it allow the factory structure to be displayed as a rough layout. But it also makes it possible to use factory planning methods for optimal spatial arrangement (e.g. Sankey diagram, logistics evaluation, especially transportation effort, area balance). It abstracts with blocks to the extent that variants can be created quickly and evaluated with sufficient accuracy in a project. This is one of the reasons why a block layout is an integral part of established procedures for factory planning.

Related topics:

- What you should know about Factory Planning

- Rough layout vs. fine layout

- Build your 3D models for layout planning with visTABLE®?

No problem, simply subscribe to our Blog-News!