Increasing productivity in supply chain management is one of the main objectives in many businesses. While managing the current plan, there can be effective strategies for lead time reduction. Reducing time to market, reducing cost, and creating better customer experiences are just a few ways an effective supply chain can add value.

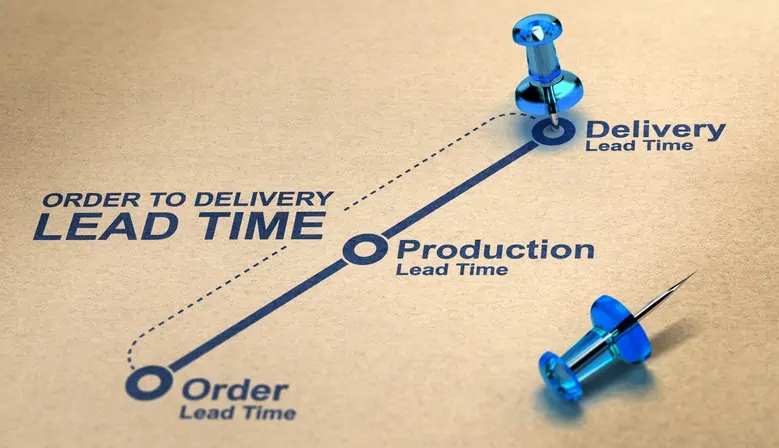

What is Lead Time Reduction?

It includes all measures to minimize the time taken from the manufacturing facility to the merchant or customer. Through this process, manufacturers and retailers are taking steps that improve consumers’ access to a broader range of products and reduce costs.

Lead Time Reduction Benefits

The benefits are essential to your supply chain and can be an excellent factor for your business, and they are namely:

Flexibility during rapid shifts in the market

It provides the option to use idle assets and having those assets pre-positioned to allow manufacturers to cut their safety stocks. The market flexibility during these rapid shifts enables a manufacturer to impact cash flow and create heightened agility for continuous improvement initiatives, resulting in improved overall efficiency.

Ability to Outpace Your Competitors

With the advanced capabilities of the full range of dynamic, automated packaging equipment and machines, you can decrease your lead time to market at a minimal cost. These solutions are customizable and flexible, which allows you to save money while still meeting your production goals.

Quicker replenishment of stock

Refinement to supply chain planning, inventory management, and logistics can help get products to your consumers faster and improve reliability. These improvements also allow companies to avoid stock-outs and lost sales.

Meeting deadlines consistently

The benefits of getting work done are immense. They supported the company’s goals, met deadlines, and improved quality and production. These are just some of how it can benefit any company.

Increases in cash flow

A comprehensive process to reduce the time it takes to get a product from your suppliers to the clients increases cash flow.

What about Process Time: isn’t this the same as Lead Time?

Whilst process time is focused on the time the thing is being worked on by an operator. Lead time is the amount of time required to accept a customer order and process it through the supply chain, including the acquisition of raw materials, initial processing, production, assembly, and packaging. Often Process time is the actual time a person spends working on a specific item or task including walking and waiting. Strategies to minimize process time, neglect the need to look at all activities in the complete supply chain.

If you want to know more about this topic, we've got you covered in our in-depth article How important is lead time in factory planning.

Lead Time Reduction Strategies

Reducing the lead time is often a significant focus for manufacturing companies, who strive to reduce the time from receiving an order to when it is shipped. Here are some strategies you can use:

Change shipping methods

By making even small changes to your shipping methods, you can gain more control over your delivery schedules which help reduce costs..

Sourcing locally

It allows you to reduce your lead times by buying locally and having items manufactured close to your distribution centre, avoiding shipping time and cost.

Vertical integration system

Vertical integration is a strategy companies use to make up for the time lost shipping products. It allows a company to produce its raw materials and other components, helping decrease lead times and save money on overhead costs.

Automation

Automation is a crucial factor. It includes using barcoding, robotics, radio-frequency identification (RFID) systems, and organizational strategies that decrease the need for human intervention during operations.

Layout Planning

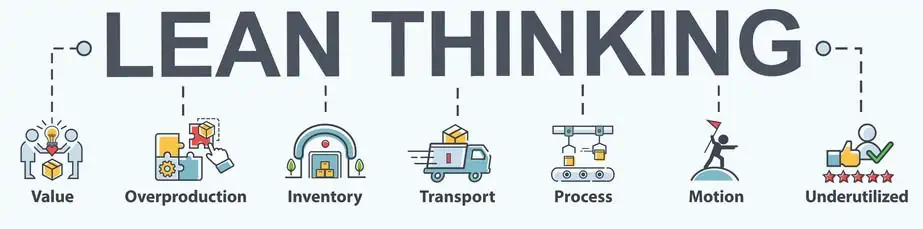

Layout planning involves many steps, from ways of organizing the data to ways of avoiding conflicts in the supply chain. Develop a lean layout. As a result, you attention goes on something largar than one process. Too often, Lean efforts focus on the little things – how can I eliminate waste in my workplace, how can I reduce changeover time. Layout planning is about the big picture. How do you organize your entire facility? Where is the waste? How can you redesign the entire organization to be consistent with the concepts of flow and just-in-time?

Sounds interesting? You can find more in our in-depth article How factory layouts depend on the value stream?

How Can You Reduce Lead Time?

Decreasing it is a crucial factor in improving your company’s production. Here are some ways that you can achieve this goal:

- Identify and implement strategies that can be done in parallel.

- Develop a lean production system that shortens cycle times as much as possible.

- Streamline the order of entry and shipping.

- Transform process layouts into product or hybrid layouts.

How to Quantify Lead Time Reduction?

It can be challenging, especially when following it on an operational level. This is because it varies by operation and department within your organization. You will need to identify the areas where the lead time is the longest. You can conduct a comprehensive root cause analysis or a service quality assurance audit. Doing it visually is very helpful.

A Value Stream Analysis or some graphical mapping tool will enable the participants to identify waste and ideas for tweaks. This will help them understand how long it takes from the time a customer order comes in until that order is delivered to the end user. The findings from this analysis will be used as a baseline for improvement activities and can be reported back to management to show what improvements have been made over time.

Are you looking for specific examples? Spaghetti diagrams, 3D visualization, or Material flow analysis are good starting points.

How to Reduce Lead Time

To help implement a plan, you’ll need to understand your supply chain. This will help you identify the areas where you can improve visibility and control. You can do this by implementing an up-to-date supply chain. This will give you a virtual picture of your supply chain and the processing time in each area. It can help you identify where you have the most room for improvement, giving you a competitive advantage.

Reducing non-value-added activities is one of the most effective strategies. Some non-value-added activities include waiting for information to arrive before proceeding, conducting unnecessary meetings and processes, high inventory levels, walking, moving semi-fninished products and safety stocks, or performing unnecessary tasks.

Reducing lead times is about improving flow. Long distances, long setup-times, batch-oriented machines, bottlenecks and poor maintenance are typical obstacles of continous flow. A good layout design will make these flows run smoothly through all processes. A visual representation of your layout will make these flows apparent to all stakeholders.

With a plan, you can ship faster and deliver more consistently. Get it done with tools that give you both visibility into your business and the ability to accelerate it. A reduction in the measure for manufacturing a product is an essential aspect of any business, as it can cut the company’s costs and increase profits. This makes products available faster, thus creating more time to focus on other essential things.

Why is Lead Time Reduction so Important?

Once you have implemented a strategy for Lead Time Reduction, you will better understand your supply chain, be better equipped to mitigate any risks and polish your financial performance. With the reduction in lead time, risk will no longer be an issue. The supply chain provides better service to your clients. You’ll also be able to meet their demand, increasing your profit margin. This will help your business to grow and reach new heights.

The overall objective is to provide our customers with the right product, at the right time, at the right price. This requires continuous monitoring and evaluation of various operations parameters while striving to reduce inefficiencies. It is achieved through several initiatives that we hope you will find valuable. Here is our top 5 list of lean production methods. Making things visible is a key principle for reducing lead times in the long term and sustainably.

No problem, simply subscribe to our Blog-News!